100 ton/day best quality processing palm oil machine in malawi

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Voltage: 380 V

- Power: 2.2 KW

- Certification:ISO9001

- Weight: based on the capacity of canola seed oil refining machine

- Dimension (length x width x height):1910*550*765 mm

- Country: malawi

Core Components: Motor, Pressure vessel, Pump, Gear, Bearing, Engine, Gearbox, Palm oil processing plant Warranty: 1 Year, Video technical and Online support, Field maintenance repair service Oil Product name: Cooking Oil Making Machine

Palm Oil Processing Machine in malawi

- Type: palm oil processing machine

- Production capacity: 98%

- Voltage: 220 V

- Key Selling Points: High Precision

- Weight: 22KG

- Dimension (length x width x height): 50*53*30 cm

What is palm oil processing? Palm oil processing in a small scale mills involves a point where harvested bunches of palm fruits are received at the mill. The bunches are stripped at the mill with machetes, the fruits are picked by hand and goes through production process. The palm oil processing project is of two (2) seasons ie. Bumper and light or lean seasons. What is a palm oil press

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

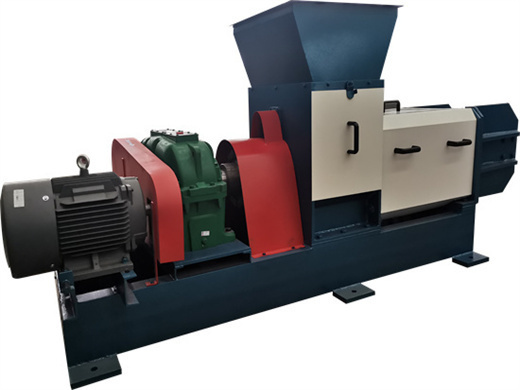

malawi screw type palm oil press machine

- Usage: palm oil

- Product Type:Wood Oil

- Processing Type:Cold Pressed

- Volume (L):120

- Purity (%): 100

- Packaging: Bulk

residual oil: less than 6% ; A screw press palm oil mill was designed and constructed to extract palm fruit for palm oil. Since it can mechanize the palm oil extraction process and maximize the oil. In the processing of crude palm oil, a screw press is the primary equipment for separating the oil palm fruit components, i.e. oil and solids.

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Palm Oil Press Machine in malawi

- Type: cooking oil extraction machine

- Production capacity: 6.5TPD

- Dimension (L*W*H): 1860*740*1310

- Voltage: 220V/380V

- Weight: 650 KG

- Oil Product Color: Yellow or customized

What is palm oil pressing machine? Palm Oil Pressing Machine (Oil Extraction) Screw pressing is the main method of palm oil extraction. In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts. How oil palm fruit is pressed? After pressing, oil palm fruit is divided into two parts: the

The basic palm oil production process of small scale palm oil processing machine is almost the same, but for different capacity, the detailed process will be a little different. Detailed information of different palm oil production machine, please contact us to get professional designs and equipment configuration for your palm oil making business.

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- Production capacity: 100

- Weight: 1000KG

- Voltage: 220V/380V

- Key selling points: high productivity

- Marketing machinery test report: provided

Palm Oil Machine. Henan Huatai Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining.

Our palm fruit oil processing plant capacity ranges from 3tph to 120tph. Welcome to contact us. Complete palm oil production process in a large-scale palm oil factory. Fresh fruit bunches (FFB) of oil palm after the fruit is harvested, it is processed in a palm oil mill, where the FFB is sterilized, digested, and pressed to extract palm oil.