Breaking Down the Investment: Virgin Coconut Oil

- Type: coconut oil refinery plant

- Usage/Application: coconut, copra

- Production capacity: 1-50TPD

- Voltage: 380V or local voltage

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): Capacity

- Country: cameroon

For example, your virgin coconut oil manufacturing plant cost will definitely be more expensive than a plant for refined coconut oil. Virgin oils also tend to have a shorter shelf life. But given growing awareness about the many health benefits of virgin oils, they also command a premium in the market, making up for the increased investment

Coconut Oil Manufacturing Plant Report 2025: Setup & Cost

- Type: coconut oil refinery machine

- Production capacity: 10-300T/D

- Voltage: 380v

- Weight: 1000kg

- Dimension (L*W*H): according to capacity

- Power (W): 10 -50kw

IMARC Group’s report, titled “Coconut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a coconut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as

The Virgin Coconut Oil Extraction process Coconut oil has long been considered a superfood because its unique blend of fatty acids provides multiple health benefits such as heart health, improved cognitive function, and weight loss. Virgin Coconut Oil (VCO) is extracted from the fresh and mature kernel of coconuts.

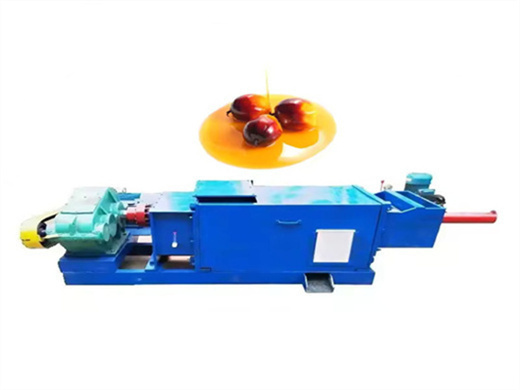

Virgin Coconut Oil (VCO) Extraction Plant - Oil Expeller

- Usage: coconut oil

- Production capacity: 100 kg/h-1000 kg/h

- Voltage: 220V/380V, 380V

- Main components: Motor, Pressure vessel, Pump, PLC, Others, Gears, Motor, Gearbox, Processing machine cooking oil

- Weight: 2100kg

- Dimension (L*W*H ): 1180*1330*1640mm

Machinery & Equipment required to setup a Virgin Coconut Oil Mill Plant. The requirement of VCO Mill Machinery and equipment usually depends on the different aspects such as processing raw materials, required pressing capacity, production cost budget and other detailed information.

This document provides design details for a coconut oil refining plant. The plant will process 10 tons of coconuts per day to produce refined virgin coconut oil. The process involves dehusking, grinding, drying, pressing, centrifuging, filtering, and refining coconut material to extract and purify the oil. The plant requires equipment for each processing step and utilities like electricity

Virgin Coconut Oil Machinery – Gemtech Projects

- Type: cooking oil refining machine

- Production capacity: 10-5000T/D

- Power: 2.2 KW

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1910*550*765 mm

- Weight: 420 KG

The demand for virgin coconut oil is increasing at a rapid pace. A large number prefer using it for physical and health benefits. At Gemtech Projects LLP, we manufacture and supply high-quality Virgin Coconut Oil Machinery in India, guaranteeing standard performance and output levels.

for RBD coconut oil and virgin coconut oil are presented in Table 1 (above). Some physical characteristics, typical fatty acid composition and Codex ranges of coconut oil are shown in Table 2 (right). It can be seen that CNO contains about 92% saturated fatty acids; this makes the crude oil very stable against oxidation. However,

Expert Tips For Coconut Oil Refining Process To Profitable Plant

- Raw Material: coconut

- Production capacity: 200 kg/h-2000 kg/h

- Dimension (L*W*H): 50*53* 30 cm

- Voltage: 220 V

- Weight: 22 KG

- Main components: Motor, Others

The production cost of refined coconut oil is lower compared to virgin coconut oil. The storage and transportation costs of dried copra are low, and the relatively mature coconut oil refining process and large-scale production can reduce the unit cost. Therefore, investing in a coconut oil refinery plant is a wise choice!

Virgin coconut oil extraction plant and coconut flour mill. Over the years, SMR Consolidated has expanded its capabilities to include the entire cycle of coconut oil production; from nuts to oil. All our processes, milling, refining, filling and final packaging are governed by strict quality control regulations relating to food safety.