Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Voltage: 380 V

- Dimension (L*W*H): 1230*1100*1570

- Main components: Electrical cabinet, hydraulic oil tank, oil cylinder, oil pump

- Warranty : 6 months

- Weight: 1680 KG

- Country: south africa

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

How is Sunflower Oil Processed?

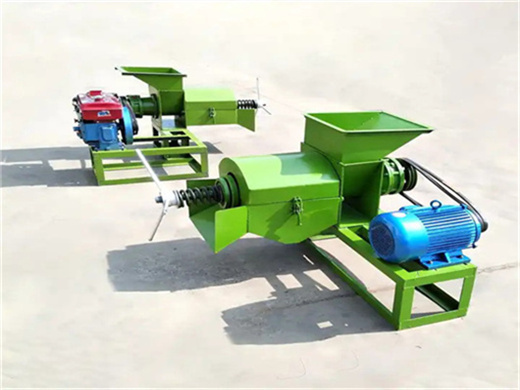

- Type: sunflower oil processing machine

- Voltage: 220V/380V/410V

- Power:2.2KW

- Certification:ISO9001

- Weight: Based on the capacity of sunflower refined oil plant

- Dimension (L*W*H):1910*550*765 mm

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

The solvent extraction process utilizes a solvent that diffuses into the prepress cake granules. The extraction process is a complex combination of several mechanisms including leaching, washing, diffusion, and dialysis (Johnson, 1997). Leaching and washing remove oil that is free and easily accessible to the solvent.

A Step-by-Step Guide on How Sunflower Oil is Made

- Usage: sunflower oil

- Production capacity: 80%

- Voltage: 110/220V

- Main components: Motor

- Weight: 1200KG

- Dimension (L*W*H): 1700*1100*1600MM

Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.

This process involves using chemical solvents to extract the oil from the sunflower seeds. After the oil is extracted, it is filtered and processed to remove impurities. Solvent-extracted sunflower oil is usually lower in quality than cold-pressed oil, as the solvents can damage the oils beneficial compounds.

HOW IS SUNFLOWER OIL EXTRACTED? - Grainvest

- Type: cooking oil extraction machine

- Supply Type: OBM (Original Brand Manufacture), OEM/ODM

- Ingredient: Hydrogenated Palm Oil

- Gender: Female, Male

- Main Ingredient: Cosmetic Paraffin

- Age Group: Adults

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning; De-hulling; Grinding; Pressing

Watch the step-by-step journey of sunflower oil production, starting with harvesting the sunflower seeds, followed by cleaning, crushing, pressing, and finally the extraction process that creates

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

- Raw Material: sunflower

- Production capacity: 100~5000T/D

- Power (W) : up to specification

- Voltage: 380v/50Hz

- Dimension (L*W) *H): 1360*950*1170mm

- Weight: as per specification

Here are the ten most frequently asked questions (FAQs) about the sunflower oil extraction process, quality, and applications, along with their answers: 1. What is the best extraction method for sunflower oil? Mechanical pressing and solvent extraction are the most common methods used for sunflower oil extraction.

Sunflower oil production line. After reading the sunflower oil production process introduced for you above, you may have a general understanding about the sunflower oil extraction process. Henan Glory Oils & Fats Engineering Co., Ltd is professional in sunflower oil extraction plant design, installation, technical consulting and so on and can