Oils Fats Refining Equipment and Turnkey Plants

- Type: peanut oil refinery machine

- Usage/Application: peanut, groundnut

- Production capacity: 80-150 kg/h

- Voltage: 110 V/220 V/380 V

- Core Components: Motor

- Weight: 700 KG

- Dimension (L*W*H): 1480 *630*1570 mm

- Country: botswana

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

High quality edible oil refinery machine manufacturer

- Type: peanut oil refinery machine

- Production capacity: 100-6000 kg/h

- Voltage: 220 V

- Main components: Motor

- Weight: 13 KG

- Dimension (L*W*H): 465*180*310 mm

Discover high-efficiency edible oil refinery machines designed for optimal oil purification and processing. Suitable for various oils like soybean, sunflower, palm, and peanut, these machines ensure premium quality oil with advanced refining technology. Enhance your production with our durable and cost-effective solutions.

Crude peanut oil refinery processing section and machine. Refining processing mainly contains the following sections: Deacidification and Degumming, Decolorization, Deodorization and Dewaxing. Advantages of Lingfine Peanut oil refinery machine Advanced designed edible oil refining process. Lingfine designs advanced and professional edible oil

peanut oil processing machine in botswana

- Usage: peanut oil

- Voltage: 220 V/380 V/440 V

- Power (W): 10 -50kw

- Certification: ISO9001/CE/BV

- Weight: According to palm oil processing capacity

- Dimension (L*W*H): 1200*400* 900mm3

Watch Video. We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for peanut oil, rapeseed oil, sunflower seed oil, cottonseed oil, Peanut oil, Peanut oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

To avoid oxidization of crude edible oil and get rid of impurities or hazardous substances, you need to set up a peanut oil refinery plant to refined crude peanut oil. There are different capacities available for the peanut oil refinery palnt. We can provide and supply small scale as well as large scale peanut oil refinery plant.

abidjan refinery contract | Supply of turnkey project for

- Type: cooking oil refining machine

- Voltage: 380V-440v

- Dimension (L*W*H): can be adjusted

- Power (W): according to process capacity

- Weight: according to process capacity

- Operation personnel: automatic control

The peanut oil production line is a production line composed of sheller, Conveyor,Roasting Machine, oil press, and Oil Filter Machine. It is suitable for small and medium-sized factories to help factories save labor time and increase oil output. The peanut oil production line can be squeezed raw or cooked. According to your own needs and budget, relevant personnel will recommend a suitable plan for you

Wide application. It can refine a variety of crude cooking oil, like peanut oil, sesame oil, rapeseed oil, palm oil and sunflower seed oil. Oil Refinery Equipment Small scale edible oil refinery machine. The small cooking oil refinery machine is suitable for small-scale oil mills or plants. It is specially designed for small oil refining

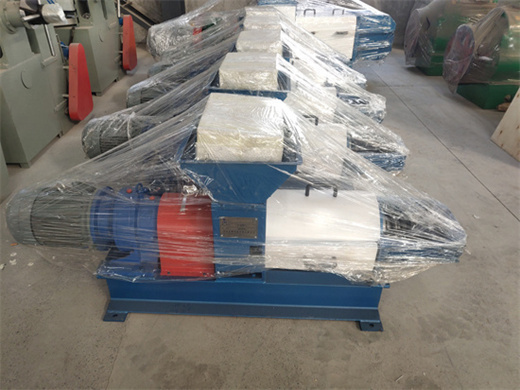

Oil Press Machine. Oil Refinery Machine.Turnkey Cooking Oil

- Raw Material: peanut

- Production capacity: 15 TONS/DAY

- Dimension (L*W*H): 2640MM*1396MM*3403MM

- Voltage: 40 HP

- Weight: 7000 KG

- Main components warranty: 5 years

Various kinds of crude oil can be refined, such as peanut oil, sunflower seeds oil, soybean oil, coconut oil, palm kernel oil, rapeseed oil, etc. The complete oil refining plant can work independently or with the whole oil production line. The capacity of edible oil refining plants can be customized.

3. Groundnut oil refining process Crude oil from oil extraction→ Degumming → Deacidification→Decoloration→ Deodorization→Refined groundnut oil - Degumming: adding phosphoric acid (85%) to reduce gum and impurities inside crude oil - Deacidification: adding alkali to neutralize free fatty acid , generates soapstock