Sunflower oil processing plant

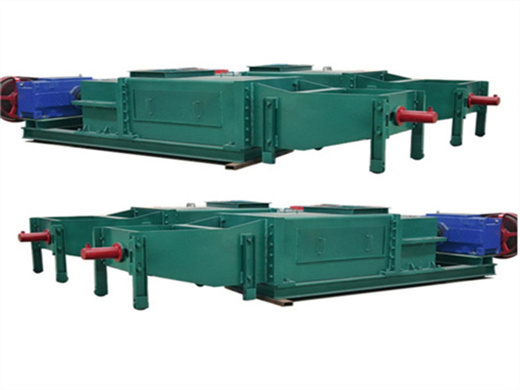

- Type: sunflower oil plant

- Usage/Application: sunflower

- Production capacity: 20-2000T/day

- Voltage:220V/380V/440V

- Weight:1200kg

- Dimension (L*W*H) :1700*1100*1600mm

- Power ( W): 1.5kw

- Country: indonesia

The most advanced equipment allows organizing a number of modern processes for the sunflower oil production, and careful laboratory control of products ensures their quality and safety. Our own fleet and railway line allow us to carry out rapid road and rail cargo delivery throughout Russia and export to more than 15 countries.

Sunflower Oil Extraction Process, Methods – A Full Guide

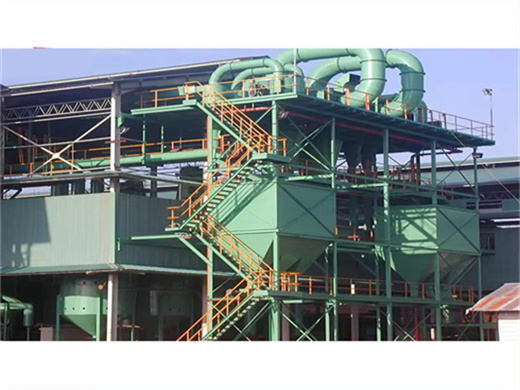

- Type: sunflower oil processing machine

- Production capacity: 5-1000T/D

- Voltage: 220V/380V/440V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing , motor, gearbox

- Main components warranty: 2 years

- Dimension (L x W x H): 1700 x 1300 x 1750 mmWeight: 30 tons, 30 tons

Sunflower oil is a mixture mostly of the polyunsaturated fat, linoleic acid (59% of total), and the monounsaturated fat, oleic acid (30% of total). In sunflower oil plant breeding and manufacturing, four types of processed oil containing different amounts of the main fatty acids are produced.

Sunflower Oil is a non-volatile oil extracted from the seeds of the sunflower plant. It has a high smoke point (450°F), which makes it ideal for high-heat applications like frying and sautéing. Sunflower oil is employed for cooking at low-to-extremely-high temperatures.

Sunflower Oil Manufacturing Plant Report 2025 | Setup Cost

- Usage: sunflower oil

- Production capacity: 12-15 TPD

- Voltage: 50HP

- Main components warranty: 5 years

- Weight: 5500 KG

- Dimension (L*W*H): 2921-1400-2743

IMARC Group’s report titled “Sunflower Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a sunflower oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as

Wide application of Sunflower Oil Production. Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system

Crude Sunflower Oil Production Cost Analysis Reports 2025

- Type: cooking oil extraction machine

- Weight: 300 KG

- Oil type: Cooking oil

- Main components: Pump, PLC

- Oilseed extraction: 90 % Oil Yield

- Processing Types: Screw Pressing

Crude sunflower oil is used to produce refined edible sunflower oil, which is further used to produce blended edible vegetable fat, mayonnaise, fat spreads, mixed edible oil, and such products. Moreover, it is extensively utilized in the production of gear oils, hydraulic oils, and other focused lubricants.

Starting a standard sunflower oil production company is indeed a capital intensive business because the amount required to set up a sunflower oil production plant is small. The bulk of the startup capital will be spent on leasing or acquiring a facility and also in purchasing oilseed oil extracting and processing machines.

Sunflower Oil Production Line for Sunflower Oil Plant to

- Raw Material: sunflower

- Production capacity: 98%

- Power (W): 10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

Sunflower Oil Production Process Introduction. Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps

Sunflower seed is one of the main oil seed in the world. According to the capacity, the sunflower seed oil extract process can divide into 1-10 tons per day, 10-50 tons per day and 30-3000 tons per day and so on