Mitigation of 3-MCPDE and GE in palm oil in Indonesia - IOPRI

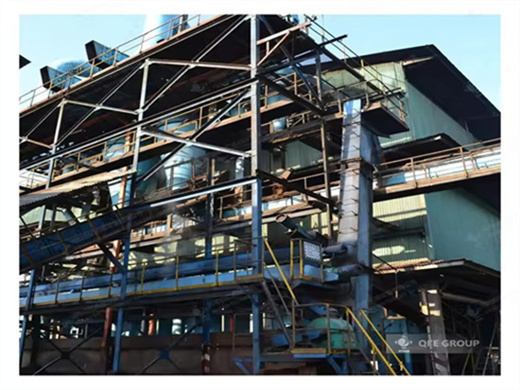

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

- Country: uganda

Ibrahim N.A. & Menon RN. (2017). Mitigation for 3-MCPD ester at palm oil mills, Features Article. Palm Oil Eng. Bulletin No 124. Malaysia Palm Oil Board. 11–15. doi:10.3390/ molecules25122927. Krisdiarto, A.W. & Sutiarso, L. (2016). Study on oil palm fresh fruit bunch bruise in harvesting and transportation to quality. Makara J. Technol. 20

Mitigation of 3-MCPDE & GE Precursors in Palm Oil Mill

- Type: palm oil processing machine

- Production capacity: Depends

- Voltage: 220V/380V

- Dimension (L*W*H): according to capacity

- Weight: according to capacity

- Power (W): according to capacity

Influence of precursors on the formation of 3‐MCPD and glycidyl esters in a model oil under simulated deodorisation conditions. European Journal of Lipid Science and Technology, 115(3), 286-294. 9. Ermacora, A., & Hrncirik, K. (2014). Influence of oil composition on the formation of fatty acid esters of 2-chloropropane-1, 3-diol (2-MCPD) and 3-

The data clearly shows that 3-MCPD/GE are mainly a challenge for palm oil processors and much less for refiners of other vegetable oils, who in their turn have to deal with TFA. Formation of 3-MCPD and GE In the past, edible oil processors have already implemented effective mitigation technologies. This has resulted in a substantial reduction of

Reduce 3MCPD and GE, palm oil contaminants | Alfa Laval

- Usage: palm oil

- Production capacity: 5TPD-100TPD

- Voltage: 380V

- Weight: 1520kg

- Dimension (L*W* H): 2600x1900x2250mm

- Power: 18.5-22kw

Recently, 3MCPD in vegetable oils has been getting a lot of attention in recent years in the edible oil industry. In fact, discussion about it has been around for decades. In 1978, 3MCPD and its esters (GEs) were identified as food contaminants in hydrolyzed vegetable proteins (HVPs.) Since then, efforts have been made to identify in other foods, including edible oils, that may contain these

Palm Oil Engineering Bulletin No. 135 [ 13 ] Options for Mitigating the Formation Of 3-MCPD Esters in Palm Oil mg kg-1 and 3.22 mg kg-1 in unrinsed CPO to 0.45 mg kg and 1.51 mg kg-1 in rinsed CPO respectively. Rinsing of CPO provided better reduction effect at both deodorisation temperatures but the effect is more prominent at lower

Mitigation of 3-MCPD esters and glycidyl esters during the

- Type: cooking oil extraction machine

- Production capacity: 50-700 kg/h

- Voltage: 220 V/110 v

- Function: Oil mill making pressing extractor machine

- Oil Raw material: Coconut

- Dimension (length x width x height): 480 x 150 x 343 mm Weight: 12 kg Main components: Motor, pump, PLC

3-Monochloropropane-1,2-diol ester (3-MCPDE) and glycidyl esters (GE) are well known process contaminants that are found relatively abundant in refined palm oil compared to other refined vegetable oils, for instance soy, canola, and sunflower oil (Albuquerque et al., 2018, Beekman et al., 2019, Jędrkiewicz et al., 2016). These contaminants are

For all of 2021, the maximum content of 3MCPDE in processed palm kernel oil is 1.25 ppm and in processed palm oil 2.5 ppm. Starting January 1, 2022, the maximum content of 3MCPDE in processed palm oil will decrease from 2.5 ppm to 1.25 ppm for integrated refineries, exporters and importers.

Webinar 3-MCPD and GE mitigation - Alfa Laval

- Raw Material: palm

- Production capacity: 20T~120T/D

- Power ( W): 11KW

- Voltage: 220V/380V

- Dimension (L*W*H): 1200*400*900mm3

- Weight: 1000kg

•3-MCPD and its esters are formed in heat-processed, fatty foods from glycerols or acylglycerides in the presence of chloride ions. Much of the 3-MCPDE found in foods is present as fatty acyl esters. •Factors contributing to 3-MCPDE in refining of palm oil: –Presence of chloride in the crude palm oil (CPO), bleaching clay and steam

and stability of palm oil. Prepared for future regulations Alfa Laval is working to ensure that palm oil producers can meet future regulatory requirements while maintaining premium quality palm oil. There are four focal points in palm oil processing where significant reductions of 3-MCPDE and GE can be achieved.