peanut oil processing machine in botswana

- Type: peanut oil refinery machine

- Usage/Application: peanut, groundnut

- Supply type: OBM (original brand manufacturing)

- Ingredient: Roman chamomile oil

- Hand ingredient: Pure natural plant essential oil

- Function: Relaxing

- Features : Improve work performance by reducing stress, Improve mood, Improve sleep, Reduce inflammation, Relieve headaches

- Country: botswana

Watch Video. We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for peanut oil, rapeseed oil, sunflower seed oil, cottonseed oil, Peanut oil, Peanut oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

abidjan refinery | Supply of turnkey project for edible oil

- Type: peanut oil refinery machine

- Production capacity: 20-2000TPD

- Voltage: 380V

- Weight: standard

- Dimension (L*W*H): standard

- Power (W): Standard

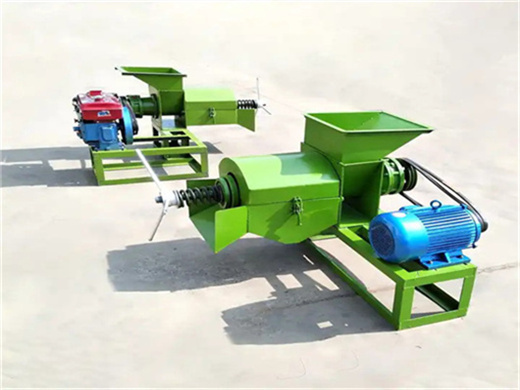

Peanut Oil Pressing Plant is fully adopted mechanical driven, it connects each oil processing machinery together to extract oil with higher oil yield and at the same time, change the single machines by manual into the semi continuous production line to liberate the workforce. Peanut Oil Press Machine is really an ideal investing item with little investment, high production efficiency and high profits!

Oil Extruder parameter: Main shaft rotatory speed:36-46r/min. Main power:15kw. Heat power:0.8kw×3. Power request:380V/50Hz. Weight:1050kg. Dimension (mm):2200×980×1920 This is the line of edible oil extraction machine, including cooking machine, oil extraction machine, refinery machine, bottle filling and cappling machine .

Crude Peanut oil refinery machine | Lingfine Machinery

- Usage: peanut oil

- Production capacity: 8-12 kg/h

- Voltage: 220V/110V

- Warranty: 1 year, long-term technical support

- Weight: 12 KG

- Dimension (L*W*H): 43.5 *27.5*28cm

Crude peanut oil refinery processing section and machine. Refining processing mainly contains the following sections: Deacidification and Degumming, Decolorization, Deodorization and Dewaxing. Advantages of Lingfine Peanut oil refinery machine Advanced designed edible oil refining process. Lingfine designs advanced and professional edible oil

Peanut Oil Refining Machine. Edible oil refining is of great importance for the specialized peanut oil mill plant for business purpose since it can greatly improve the quality, including the color, taste, shelf time and more. The main process of peanut oil refining is degumming, deacidification, decolorizing and deodorizing.

Small scale Peanut oil refining machinery - qieoilrefinery

- Type: cooking oil refining machine

- Configuration: Stationary

- Lubrication Style: Lubricated

- Power Source: AC POWER

- Silent: Yes

- Voltage: 220v/110v (can be customized)

Batch-type edible oil refining equipment offers a practical solution for small-scale edible oil production, combining flexibility, efficiency, and high-quality output. Its modular design, ease of operation, and cost-effectiveness make it an excellent choice for the small-scale oil mill plant, ideal for producing high-quality refined edible oil

Peanut oil refinery plant is a set of machines, with which we can get standard edible peanut oil for cooking. In the production process of peanut oil refinery plant, we utilize the physical methods and chemical processes according to the different usage and requirements to get rid of the harmful impurities and needless substance in the crude

Batch Type Small Edible Oil Refining Plant - Oil mill

- Raw Material: peanut

- Voltage: 220V/380V

- Dimension (L*W*H ): 1200*400*900mm3

- Power (W): According to the capacity of palm oil processing machine

- Weight: According to the capacity of the palm oil processing machine

- Certification: ISO 9001

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery plant: After solvent extraction, there are some impurities in crude peanut oil. To get the higher quality final product oil, the crude peanut oil should be refined by oil