How Coconut Oil Is Made: The Surprising Truth & Process

- Type: coconut oil processing plant

- Usage/Application: coconut, copra

- Production capacity: 30-450 kg/lot

- Voltage: 220V/380V

- Main components: Motor

- Weight: 230kg

- Dimension (length*width*height): 1200*800* 1160mm

- Country: nairobi

The journey of coconut oil production progresses with the heating of either the freshly extracted coconut milk or the dried coconut meat known as copra. In the wet mill method, the coconut milk is gently heated, allowing the lighter oil molecules to separate and rise to the top, a process that can be enhanced by fermentation or other separation

Coconut Processing Plant Report 2025: Setup & Cost - IMARC Group

- Type: coconut oil processing machine

- Production capacity: cooking seed processing 50 to 200 tpd

- Voltage: 220V /380 V/440 V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

IMARC Group’s report, titled “Coconut Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a coconut processing plant. It covers a comprehensive market overview to micro-level information such as unit operations

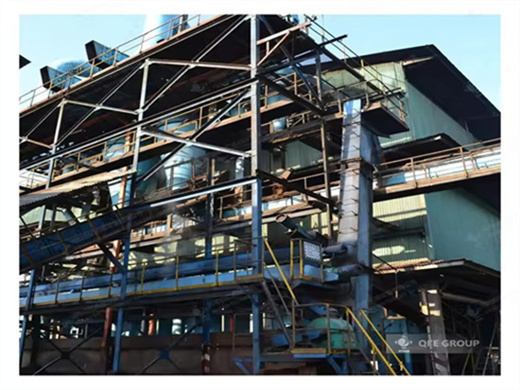

Coconut oil processing plant. Explore the world of coconut oil production with Huatai's advanced facilities, designed for high efficiency and maximum yield. Our video highlights our capacity to process vast quantities of coconut oil, from 30 to 1000 TPD, and our sophisticated solvent extraction techniques that ensure every drop of oil is captured.

Coconut Oil Manufacturing Process Flowchart

- Usage: coconut oil

- Voltage: 230-380-430

- Power (W): 40 kw/h

- Certification: CE and ISO9001

- Weight: 30 tons

- Dimension (L*W* H): 20m*16m*15m

Here are some business opportunities in coconut oil production business at many places around the world including India, Indonesia, Philippines, south africaia and Africa. Equipment & Machinery for starting Coconut oil Manufacturing business: Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business:

The Virgin Coconut Oil Extraction process Coconut oil has long been considered a superfood because its unique blend of fatty acids provides multiple health benefits such as heart health, improved cognitive function, and weight loss. Virgin Coconut Oil (VCO) is extracted from the fresh and mature kernel of coconuts.

Coconut Food Production

- Type: cooking oil extraction machine

- Production capacity: 130 ~ 200 kg/h. Voltage: 220 V, 380 V. Customer requirements

- Dimension (length*width*height): 1940*700*780 mm

- Raw material: carbon steel

- Main components: engine oil

- Weight: 550 KG

Coconut oil is rich in saturated fatty acids and low in unsaturated fatty acids. The different fatty acids present in coconut can range from C6-C18 carbon atom chains. Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used.

For example, your virgin coconut oil manufacturing plant cost will definitely be more expensive than a plant for refined coconut oil. Virgin oils also tend to have a shorter shelf life. But given growing awareness about the many health benefits of virgin oils, they also command a premium in the market, making up for the increased investment in

The Coconut Value Chain in Africa: Growth Potential under

- Raw Material: coconut

- Production capacity:50-1000 kg/h

- Dimension (L*W*H):2200*1500*1800 mm

- Voltage:380 V

- Weight: 1400 KG

- Main components:Motor, olive oil processing machine

The country has a well-established coconut processing industry, with products such as coconut oil, coconut water, and coconut-based snacks being popular in the domestic market. nairobi: While geographically located off the eastern coast of Africa, nairobi is known for its significant coconut production. The country is one of the largest

They also use virgin coconut oil machinery. They use a high-speed centrifuge to segregate the virgin coconut oil from raw coconut milk. In the fermentation method, they keep the coconut milk for 24 hours to ferment it. The process is natural, and the virgin coconut oil floats on the top. Then they will scoop out this layer of the oil and filter it.