Peanut Oil Production Line,Peanut Oil Pressing Plant - Oil mill

- Type: peanut oil refinery plant

- Usage/Application: peanut, groundnut

- Voltage: adjustable

- Power (W): According to capacity

- Certification: ISO9001

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Country: tanzania

Small-scale peanut oil plant (1-10 TPD): Simple mechanical pressing machines and basic refining units. Medium-scale peanut oil plant (10-50 TPD): More advanced pressing equipment, potentially combined with solvent extraction and semi-automated refining systems.

(PDF) Cottonseeds and Crude Peanuts Oils Production

- Type: peanut oil refinery machine

- Production capacity: 1t/day-1t/hour

- Voltage: 220V/380V

- Main components: motor, gear, bearing, motor, gearbox

- Weight: 800 KG

- Dimension (L*W*H)): 1700*1100* 1600mm

The oil refining steps are different in all cases. This variability of oil refining process has a negative impact on the quality of the oil produced in lusaka (Zio et al., 2020). Also, poor

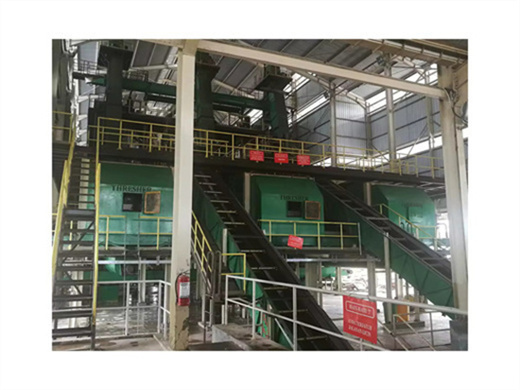

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

mobile oil refinery plants for sale in lusaka

- Usage: peanut oil

- Production capacity: 40TPH, 80TPH, 120TPH

- Voltage: 220V/380V

- Weight: depends on mode

- Dimension (L*W*H): depends on mode

- Power (W) : 11KW

Peanut is very common oil bearing material, so the technology of peanut oil extracting is relatively mature. Our Company is the largest peanut oil processing machine manufacturer and supplier in China. We are focused on providing the most advanced oil processing expeller to help our customer minimize cost and improve oil output. We have various peanut oil extraction machine for different peanut oil production requirements. Our peanut oil machine is featured with high quality and low price, which makes it popular in the world. It fully makes use the mechanical forces to squeeze oil out from the peanut.

Continuous refining plant is suggested for production of large capacity, while batch or semi-continuous types aremore suitable for medium and small oil refining workshops. Others, such as the reliability of the equipment and technology,labor productivity, theconsumptionrate of auxiliary materials, steam, water and electricity.

groundnut oil refinery plant processing peanut oil

- Type: cooking oil refining machine

- Production capacity: 350-7000 kg/h

- Power (W): 7.5 KW

- Voltage: 380 V

- Dimension (L*W* H): 900*850*1550mm

- Weight: 300KG

Groundnut/ Peanut oil refinery plant. Peanut oil refining process detailed description: (1)Pump crude peanut oil into refining tank and heat with conduction oil, and the temperature will reach about 70 C-80 C after one hour. Add acid or alkali to separate according to the acid value.

In general, there're 3 types of peanut oil refinery plant, batch type, semi-continuous and full-continuous. 1-2-3-5-10TPD batch type peanut oil refinery plant. 10-15-20-25-30-50TPD semi-continuous peanut oil refinery plant. 50-80-100-150-300-600-2000TPD full-continuous peanut oil refinery plant. Different capacity peanut oil refinery machine

Peanut Oil Press Machine. Peanut Oil Expellers For Sale.

- Raw Material: peanut

- Production capacity: 1t/day-1t/hour

- Dimension (L*W*H): 2100*750*1500mm

- Voltage: 380v

- Weight: 550KG, 550kg

- Core Components: gear, bearing, motor oil

The Peanut Oil Press Machine is a specialized equipment designed to extract oil from peanuts and other oilseeds with precision, efficiency, and minimal waste. We offer complete peanut oil production lines with capacities ranging from 1 TPD to 5,000 TPD.

For medium-sized peanut oil production line, the processing capacity is generally 10TPD-50TPD. The main way to obtain the gross oil by pressing. However, in order to further improve the quality of the crude oil, we will add cleaning equipment such as magnetic separator, vibrating cleaning sieve, wind separator, etc., to remove impurities such as leaves and metals from the raw material before steaming and pressing. This will further improve the quality of the oil and reduce the wear and tear on the pressing equipment. At the same time, after the press, we will add more perfect gross oil cleaning equipment.