Oil Expellers - Peanut Oil Milling Plant Manufacturer

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 1TPD-1000TPD

- Voltage: 380V/50HZ

- Key selling points: Multifunctional

- Weight: 100 tons

- Dimension (L*W*H): 60*10*7m

- Country: ethiopia

This Peanut Oil Extraction Machine can crush peanut, ground nut, linseeds, copra, mustard seeds, palm kernels, seeds, castor, neem, sun flower seeds. We use superior raw material to fabricate this Peanut Oil Extraction Machine.

Groundnut Oil Mill / Extraction Plant Manufacturer & Exporter

- Type: peanut oil processing machine

- Production capacity: 100% edible oil solvent extraction machine

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L* W*H): Depends on its capacity

- Power (W): depends on its capacity

We provide small scale to large scale peanut oil extraction plant ranging from 5 TPD to 500 TPD. The major groundnut producing countries in the world are China, India, south africaia, USA, Myanmar, Tanzania, Argentine, Chad, malawi, Cameroon, Ethiopia, Brazil, south africa, Ghana, Sudan, indonesia, lusaka and Indonesia.

The Peanut Oil Press Machine is a specialized equipment designed to extract oil from peanuts and other oilseeds with precision, efficiency, and minimal waste. We offer complete peanut oil production lines with capacities ranging from 1 TPD to 5,000 TPD.

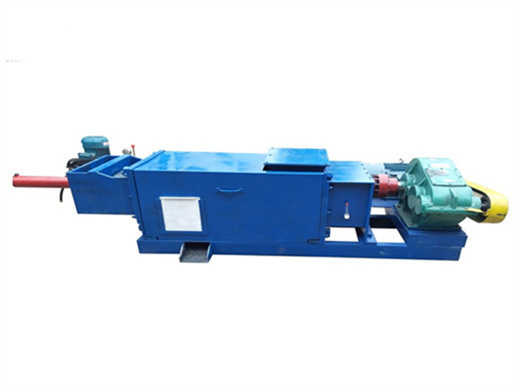

Oil Extraction Machine - Peanut Oil Extraction Machine

- Usage: peanut oil

- Production capacity: 5TPD

- Voltage: 220V/380V

- Weight: 800kg

- Dimension (L*W*H): 1700* 1100*1600mm

- Power: 5.5kw

FEATURES :Steel : Each of 36″ Long Eliminates the difficult task of removing box for replacement of worms.Steel Casted Chambers : Reduces time and labour for relining of Cage Bars The main Shaft of the Expeller is of alloy steel construction, fitted with High Pressure Worms, hard faced, with a highly wear resistant alloy.Shaft Withdrawal : The main Worm Shaft can be withdrawn easily without

There are corresponding machines and oil extraction axuliary equipment to help peanuts pretreatment process. Peanuts Groundnuts Processing Machines. After extracted from the solvent extraction plant or peanut oil extraction machines, the crude peanut oil should be filtered and refined through professional oil refining process to improve the

80-1, 200 Tpd High Rate Solvent Extractor Peanut/Rice Bran

- Type: cooking oil extraction machine

- Voltage: 220V/380V/440V

- Dimension (L *W*H): 48m*12M* 15M(30TPD)

- Power (W): 18.5 KW/T

- Weight: 30 tons

- Certification: ISO9001

The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical production”. The fragrant peanut oil obtained by pressing process maintains the natural ingredients and aroma of peanut oil, and it is rich in antioxidant vitamin E and has a long shelf life, so there is no need to add chemical antioxidants for storage; it is a pure natural oil products that are produced by combination of modern and traditional technology.

For peanut oil extraction, we recommend a combination of mechanical extraction and solvent extraction to achieve a high oil yield without compromising on oil quality. There are many different peanut oil extraction machines that you can use for these processes, depending on your desired product qualities and the scale of your operation.

Complete edible oil turnkry project contractor - Hongde Oil

- Raw Material: peanut

- Production capacity: 5TPH

- Power (W) : 10-35kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 3000*5000*10000mm

- Weight: 5T

Complete solution for edible oil equipment engineering. Henan Hongde Cereals And Oils Machinery Co.,Ltd. is a large-scale oil machinery manufacturing enterprise.

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.