Oil Seeds Extraction - JJ-Lurgi

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100% of the cooking machine price

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W*H): Depand according to its capacity, according to the capacity

- Power (W): Depends on its capacity

- Country: johannesburg

In Asia, extracting oil from soybean, palm kernel and rice bran are the most popular applications for our solvent extraction plant. JJ-Lurgi has successfully delivered many milestone projects including a 5000TPD soybean extraction plant and 1100TPD palm kernel extraction plant, the biggest capacity in the SEA region.

EXTRACTION OF DATE PALM SEED OIL (PHOENIX DACTYLIFERA BY

- Type: palm oil processing machine

- Production capacity: 100TPD

- Voltage: 380V/50Hz

- Weight: depends on capacity

- Dimension (L*W*H): 1950*1050*2250mm

- Power: 17KW, 17KW

Solvent extraction technique [17, 18] is one of the cheapest and most efficient processes, applied to produce oil from seeds. Jojoba oil, soybean oil, palm oil, jatropha oil and many other oils are produced by this method. The main objective of this research work is to produce a bio-oil from Date Palm seeds with the help of

The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a

Oil Press Extractor | Strong and durable edible oil

- Usage: palm oil

- Production capacity: 10-5000 tons

- Voltage: 380 V 440 V

- Weight: According to the production of cooking oil expeller machines

- Dimension (L*W*H): Depends on the capacity of the cooking oil expeller machines

- Power (W ): Depends on the cooking oil expeller machines production every day

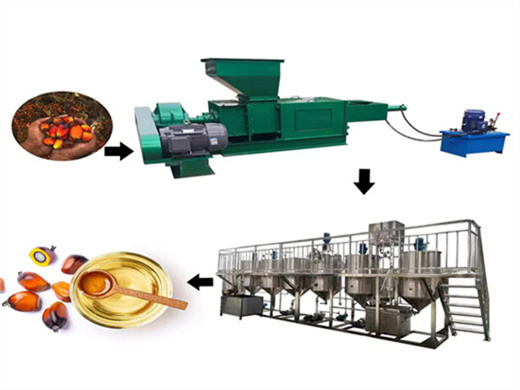

The most important equipment that is required in the production of palm oil is the palm oil expeller press or palm oil milling machine. The whole production process revolves around the extraction machine and this include sterilization, threshing, sterilizingas well as oil clarification. However, oil milling machines vary a lot depending on how the plant is going to be mechanized. For Instance, your palm oil milling machine doesn't need a thresher if the threshing process is going to be done manually by laborers.

A food grade solvent known as hexane is used to extract the remaining 5% – 6% of residual crude palm oil (CPO) available in palm-pressed fibre, thereby enhancing oil extraction rate (OER) by 0.5%. Palm Kernel Oil Extraction (PKOE) Plant, is designed to extract the oil from kernel cake by means of solvent. This shall extract an additional 3% PKO.

Palm Kernel Oil Solvent Extraction Line

- Type: cooking oil extraction machine

- Voltage: 380V/440v

- Power (W): 20-50KW

- Certification:ISO9001/BV/CE

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

Huatai’s palm kernel oil pressing and extraction production line can flexibly adjust the process according to the characteristics of the palm kernel: For palm kernels with high shell content, the kernel-shell separation link is strengthened, and multi-stage vibrating screens and wind sorting devices are added to control the shell residue residue rate below 3%; If the moisture content of the

investigated the extraction of the ground johannesburgn date seeds’ oil through a dynamic pilot-plant system using the supercritical carbon dioxide as the solvent. The effects of pressure (150-250 bar), temperature (313-333 K) and particles’ diameter (0.3-0.9 mm) on the extraction yield and fatty acids’ composition were studied.

Goyum Screw Press - Oil Processing Machine Manufacturer

- Raw Material: palm

- After-sales service: 2 years

- Structure: Vertical

- Warranty: 2 years

- Press series: as description

- Voltage: 220V

The company has attained prominent leadership in the field of Complete Vegetable Oil Extraction Mill, Solvent Extraction Plant & Edible / Cooking Oil Refinery Plant. Why Us We are serving our valued customers to their complete satisfaction through efficient management and excellent workmanship, which we continue to maintain with our untiring

The design, manufacturing, and installation are all CE and ISO quality approval. Our experience in palm oil making machine designs more than 60 years and gets national patent certificates of multiple oil milling production lines. 1. Sterilize. As the first step in palm fruit crushing, sterilization is crucial to the quality of palm oil. 2