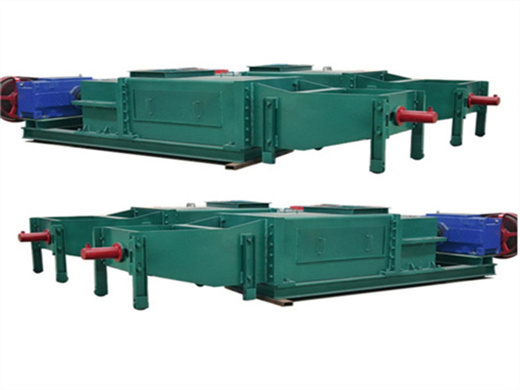

Palm Oil Decanter - Palm Oil and Palm Oil Sludge Separation

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 60%

- Voltage: 220V/380v/customized

- Main components: Motor, PLC, Other

- Weight: 260 KG

- Dimension (L*W*H): 800*1200*1300mm

- Country: botswana

The solid phase moisture content after separation can be reduced to less than 30%, the oil content in the separated water does not exceed 1%, and the solid recovery rate reaches more than 95%. ZK decanter is an efficient and reliable equipment that can provide palm oil processing companies with reliable and stable palm oil extraction solutions.

palm oil decanter - Alfa Laval

- Type: palm oil processing machine

- Voltage: 220V 50Hz

- Power (W): 1000

- Material: Stainless steel

- Dimension (L*W*H): 520*520*500mm

- Weight: 15 kg

The palm oil decanter centrifuge offers maximum oil recovery from sludge underflow or empty fruit bunch liquor with low energy consumption, excellent solid dryness and high-quality separation. The PANX is a proven decanter for the processing of crude palm oil and is well suited for the heavy duty and tough environment of the application.

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as

DECANTER CENTRIFUGE FOR CRUDE PALM OIL PROCESS

- Usage: palm oil

- Product material: carbon steel and stainless steel

- capacity: 10-1000tpd

- Function: Automatic

- Quantity: according to capacity

- Voltage: 220v/380v/other

Decanter centrifuge for crude palm oil process. The PAWT series 3-phase decanter separates the pressed crude oil mixture that comes from the underflow of the main settling tank into an oil phase, a dry solids cake and virtually oil-free wastewater. The oil phase is sent to a purifier, which polishes the palm oil and reliably removes even

Find a wholesale 10tpd edible oil processing machine to help you provide pure, chemical-free oil. Visit Alibaba.com for a wide selection of oil pressers that meets your needs.

1-10TPD Complete Set Palm Oil Processing Machinery

- Type: cooking oil extraction machine

- Production capacity: 80-150 kg/h

- Dimension (L*W*H): 2000 *700*1900mm

- Voltage: 380 V

- Weight: 565 KG

- Main components: Motor

Palm Oil Mill: Palm oil production begins with palm oil seeds. As oil palms have a productive life of 25-30 years, the choice of seeds will impact production for decades to come. The harvested FFB are transported in trucks from the plantations to the Palm Oil Processing Plant, where they are sterilized using steam. This prepares the FFB for

The document describes Alfa Laval PANX decanter centrifuges used for processing crude palm oil. PANX decanters efficiently separate palm oil mixtures into dry solids, water, and recovered oil fractions. Key features include wear-resistant materials to minimize downtime, and control systems for optimization. PANX decanters are suitable for palm oil mills of various sizes and applications such

Alfa Laval PANX range of decanters for crude palm oil

- Raw Material: palm

- Production capacity: 30 kg/h

- Dimension (L*W* H): 800*650*110 mm

- Voltage: 220 V

- Weight: 530 KG

- Main components: motor, others

oil for maximum oil recovery with minimum oil losses.The PANX range therefore includes decanters suitable for every size of palm oil mill, from 30 to approximately 90 tons of fresh fruit bunches (FFB) per hour, and for a variety of crude palm oil applications. These include: • Combined clarification and purification of pressed oil as

required oil purity and keep oil losses to the heavy phase in check. CRUDE OIL PROCESS An ANDRITZ 3-phase decanter and nozzle separator can be used in combination to minimize the oil loss from the fresh fruit bunch (FFB) and further optimize the palm oil mill effluent (POME). With the underflow from the oil sedimentation tank used as the decanter