6YZ-180 Hydraulic Oil Press Machine

- Type: cottonseed oil press machine

- Usage/Application: cottonseed

- Voltage: 220V/380V

- Power (W): 15kw

- Certification: ISO9001

- Weight: 1200kg

- Dimension (L*W*H): 1700 *1300*1600

- Country: lusaka

Cottonseed oil is a vegetable oil extracted from the seeds of the cotton plant after the cotton lint has been removed. It’s composed of linters(10%), cotton shell(40~45%) and kernel. the oil content of cotton seed is 15%-25%, the oil content of kernel is 30%-40% after decorticating. Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage.

Seed Oil Press Machines for Sale-Industrial Oil Press

- Type: cottonseed oil processing machine

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5 KW

ZY24(202-3) type pre-pressing machine’s large capacity, small workshop area, low power consumption, less operation management and maintenance work make it suitable for squeezing sunflower seed oil in large vegetable oil plant.

The oil drip through small openings that do not allow seed fiber solids to pass through. Afterward, the pressed seeds are formed into a hardened cake, which is removed from the machine. Oil expeller machine is the soul equipment of the pressing process, it can be divided into small oil press and high capacity oil press according to its capacity

Soybean Cotton Seed Oil Making Press Machine in lusaka

- Usage: cottonseed oil

- Production capacity: 10T-3000TPD

- Voltage: 220V/380V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636* 2345

- Power (W) : Capacity

This oil press machine for cold-press with raw materials, and the materials can be directly into the press effectively. Widely used for canola, soybean, peanut, sunflower seed, cottonseed, tung seed and other oil crops. Oil cake residue can be used as fertilizer, feed and so on. The machine composes of Base frame, oil filtering system, drive

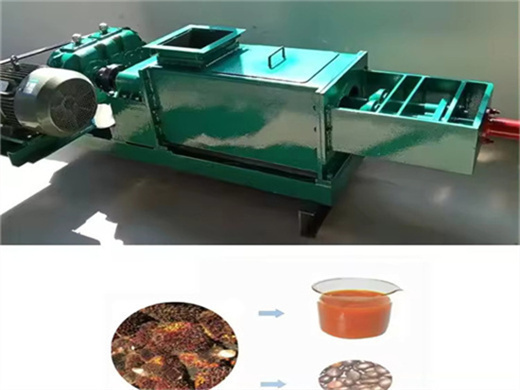

Cotton Seeds Oil Press Machine: Cottonseed oil extraction involves a series of steps, including delinting, dehulling, and flaking of the seeds. The flaked seeds are then subjected to high-pressure screw pressing to extract the oil, which is further refined to improve quality and stability.

Price Cottonseed Oil Press Machine Wholesale in lusaka

- Type: cooking oil extraction machine

- Production capacity: 10T-100T/D

- Power (W) : According to the actual situation

- Voltage: 220V/380V

- Dimension (L*W*H) ): According to the actual situation

- Weight: According to the actual situation

The export price of cottonseed oil from lusaka has seen a steady increase over the past five years. In 2018, the price per kilogram was $0.45, which increased to $0.50 in 2019. In 2020, the price rose to $0.55, and in 2021 it further increased to $0.60.

Cotton seed oil expeller are readily available with various companies assembling machines that are well versed for small oil mill of cotton. The expeller come in different size and shapes even for the small-scale producers with limited spaces. Small oil mill factory encourages self-employment as more jobs are generated. Farmers are able to use by-products of their cotton production to use. Here is a brief process of small scale cottonseed oil extraction.

Cotton Oil Extraction Machine in lusaka

- Raw Material: cottonseed oil

- Production capacity: 150-250 kg/h

- Dimension (L*W*H): 1800* 1350*1700mm

- Voltage: 220v/380v

- Weight: 1100 KG, 1100kg

- Main components: Motor

What is cotton seed oil expeller machine? Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton seed oil expeller machine is to forcefully push the cottonseeds through the chamber by

The YZS series automatic oil press is an advanced cotton seed oil extruder which is developed on the previous single oil press machine according the market demands. It has strengthen the function of frying and automatic controlled temperature, which has changed the traditional way for increasing dry cake's temperature, therefore it reduced the working time, and also reduced the waste of power