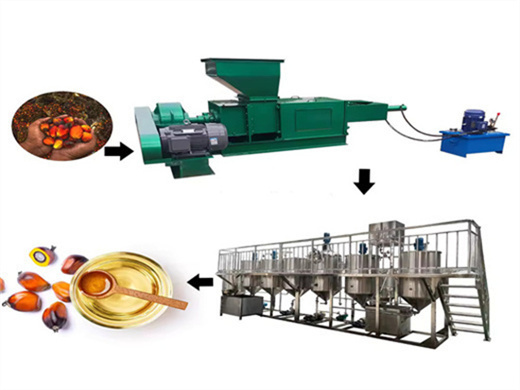

Palm oil refinery process, chemical refining and physical

- Type: palm oil refinery plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 5 tons to 200 tons per day

- Voltage: 380 V

- Main components: Motor, pressure vessel, pump, bearing, motor oil

- Weight: 10000 KG

- Dimension (L*W*H): According to production capacity

- Country: zambia

Continuous palm oil refinery (50-600tpd) 30TPD ,50TPD,100TPD,200TPD,400TPD (Suitable for industrial scale palm oil mill plant) Middle sized palm oil refinery plant. Recommed reading: 1-10tpd small scale palm oil refinery plant. Continuous palm oil refinery plant. Crude Palm Oil (CPO) is mainly further processed into edible oil for food purpose.

Palm oil processing and production process - Alfa Laval

- Type: palm oil refinery machine

- Production capacity: 3-60TPD

- Voltage: 380v or according to local voltage

- Weight: 1000 kg

- Dimension (L*W) *H): According to the capacity of the cooking oil making machine

- Power (W): 11KW

A full range of palm oil milling equipment, with everything you need for your oil room and (crude palm oil) CPO washing; Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing; Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield

Batch type is the ideal choice for mini and small sized production (1-20TPD), while the latter two are normally designed for middle-large size production line (10-50TPD). (Read more: Comparation of Batch Refinery, Semi-continuous Refinery and Continuous Refinery Plant) Palm Oil Physical Refining Plant

Crude palm oil refining methods and palm oil refining process

- Usage: palm oil

- Production capacity: 10-500 TPD

- Voltage: 380 V

- Weight: According to the request of the edible oil processing plant

- Dimension (L*W) *H): According to the capacity of the edible oil processing plant

- Power (W): according to the request of the edible oil processing plant

Our company is specialized in palm oil refinery plant. We can provide the palm oil refinery plant from 1 ton to 1000 tons. In general, batch type palm oil refinery plant is with capacity 1-20TPD; The semi-automatic palm oil refinery plant is suggested with capacity from 20-50TPD; And continuous palm oil refinery plant is used for capacity above

According to the type of refining, Henan Glory divides it into Batch type palm oil refinery plant (0.5-20tpd), Semi-continuous palm oil refinery plant (10-50tpd) and Full-continuous palm oil refinery plant (≥30tpd).

Physical Refinery Plant - PALMINDO

- Type: cooking oil refining machine

- Main components of the product: Motor

- Voltage: 220 V, 380 V

- Dimension (length x width x height): 500X500X660Material: 304 316 stainless steel

- Weight: 40

- Power: 180

PALMINDO’s primary core business is Refinery and Fractionating raw materials (Crude Palm Oil/CPO and Crude Palm Kernel Oil/CPKO). PALMINDO has 2 refinery plants with joint capacity of 1500 MTPD. Our modern and highly integrated production facilities are maintained by a team of highly skilled workforce.

Oil grade: high; Processing Type: refined; Process: full continuous; Moisture and volatile: 0.08%; Physical refining has several advantages compared to classical chemical one: − improved yield − lower investment cost − less environmental impact (no soapstock to be. Physical refining of sunflower oil is discussed in details.

Palm Oil Mill Plant Production Line - Hongde OIL MACHINE

- Raw Material: palm

- Production capacity: 60-400kg/h

- Dimension (L*W*H): 1800*1200*1550mm

- Voltage: Customizable

- Weight: 1100kg

- Warranty: 1 year, 12 months

The palm oil degumming and deacidification process uses a washing method to separate soap residual from mixing oil, providing preparation for the next step palm oil refinery machine. Bleaching Process. The palm oil bleaching process is mainly used to remove oil pigment, residual soap, and metal ions during palm oil refining machine.

The role of palm oil refinery plants. PALM OIL REFINING. Crude palm oil comprises the products of hydrolysis and oxidation as well as unwanted flavours and colours. Palm oil refinery plants are designed to eliminate these undesirable components. Palm oil refining involves four major steps. Step 1: degumming.