DECANTER CENTRIFUGE FOR CRUDE PALM OIL PROCESS

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Voltage: 230-380-430

- Power (W): 40 kw/h

- Certification: CE and ISO9001

- Weight: 30 tons

- Dimension (L*W* H): 30m*16m*15m

- Country: south africa

The PAWT series 3-phase decanter separates the pressed crude oil mixture that comes from the underflow of the main settling tank into an oil phase, a dry solids cake and virtually oil-free wastewater. The oil phase is sent to a purifier, which polishes the palm oil and reliably removes even extremely small contaminants. The palm oil sludge

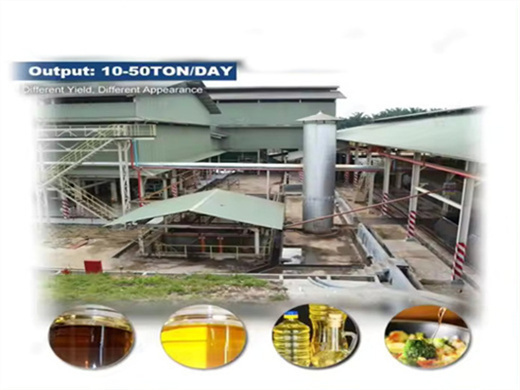

SEPARATION EFFICIENT TECHNOLOGY FOR HIGH OIL RECOVERY - Andritz

- Type: palm oil processing machine

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Weight: According to the cooking oil processing capacity

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): 10-50kw

the palm oil mill effluent (POME). With the underflow from the oil sedimentation tank used as the decanter feed, the 3-phase process delivers an oil purity in the light phase of more than 95% and an oil loss in the heavy phase of less than 1%. The heavy phase, which still contains oil as an emulsion, can be treated with a nozzle separator.

As a protection against erosion, the PAND palm oil separator contains several erosion guards and liners. Decanter centrifuge. The PAWT series 3-phase decanter separates the pressed crude oil mixture that comes from the underflow of the main settling tank into an oil phase, a dry solids cake and virtually oil-free wastewater.

Centrifuge - 3-Phase Separating Decanters for Oil Recovery

- Usage: palm oil

- Voltage: 380V

- Power (W): 20KW

- Overseas installation: Yes

- Weight: 5500KG

- Dimension (L*W*H): 2200*1600*2150mm

The big advantage of the 2-phase separating decanter for olive and palm oil recovery is the enormous savings when it comes to dilution water. Nozzle Separators for Oil Recovery Nozzle separators are used in the conventional process with vertical clarifiers in palm oil mills.

The application range of the 3-phase centrifuge Extraction of fats, oils and biofuels In the oil and fat recovery process, the base materials contain solids, water and oil.Using the Tricanter® they can be simply separated from each other.

Palm Oil Decanter - Palm Oil and Palm Oil Sludge Separation

- Type: cooking oil extraction machine

- Production capacity: According to your capacity

- Power(W): According to your requirement

- Voltage: 220V/380V/440V

- Dimension(L*W*H): According to your requirement

- Weight: According to your requirement

This equipment can efficiently separate palm oil, water and impurities. The solid phase moisture content after separation can be reduced to less than 30%, the oil content in the separated water does not exceed 1%, and the solid recovery rate reaches more than 95%. ZK decanter is an efficient and reliable equipment that can provide palm oil

One of the defining differences among industrial centrifuges is between two-phase separators and three-phase separators. “Two-phase” and “three-phase” refer to how many materials the centrifuge can separate at once. A two-phase separator, like the CentraSep S-126, is generally used to separate a liquid from a solid. (That’s why two

3 Phase Disc Stack Separator - GN Separation Equipment

- Raw Material: palm

- Production capacity: 50T~150TPD

- Power (W) : 16KW

- Voltage: 220V/380V

- Dimension (L*W*H): related to capacity

- Weight: according to capacity

It can also discharge solid phase materials. Compared with the 3 phase decanter centrifuge, the 3 phase disc separator has larger rotation speed and G force. The 3 phase decanter centrifuge usually has a separation factor of about 3000G, while the 3 phase disc stack separator G force is up to 12000G.

Three-phase decanter centrifuge is an efficient and reliable centrifugal solid-liquid separation equipment that rapidly separates mixtures into two distinct liquid phases and one solid phase. It is widely used for three-phase separation in various industries, including food waste, as well as liquid separation in applications such as edible oil