Centrifuge - 3-Phase Separating Decanters for Oil & Gas

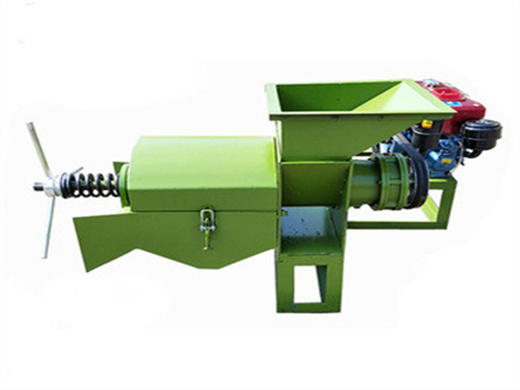

- Type: sunflower oil machine

- Usage/Application: sunflower

- Production capacity: 15~20 tons/day

- Voltage: 220V/380V/440V/415V

- Warranty: One year warranty against manufacturer defect.

- Weight: 0 KG

- Dimension (L*W*H)): 8.8 *4.7*12.2 ft

- Country: nairobi

Our 3-phase decanters of the new ecoforce series combine high performance with low energy consumption. Together with the decanter featuring the super pond depth design, the integrated summationdrive ensures that energy consumption has been reduced by a further 30 percent.

Decanter Centrifuges for Two-Phase and Three-Phase Liquid

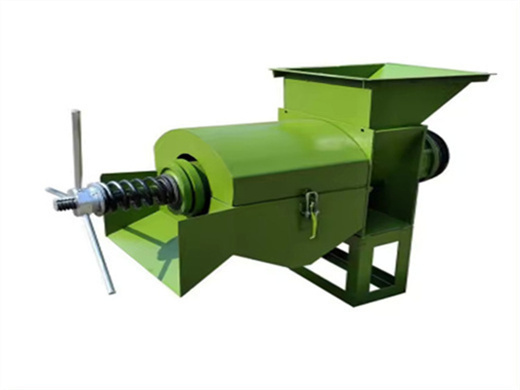

- Type: sunflower oil processing machine

- Production capacity: 20-2000TPD

- Voltage:220V/380V

- Certification:CE,ISO9001

- Dimension (L*W*H):1200*400*900mm3

- Power (W): according to capacity

These machines are flexible enough to cope with a wide fluctuation in the feed material and still achieve excellent clarification and dewatering performance producing a relatively dry separated solids cake on many processing applications. Learn More. DecaOil (3) Three-Phase Decanter Centrifuges

Three-phase decanter centrifuge is an efficient and reliable centrifugal solid-liquid separation equipment that rapidly separates mixtures into two distinct liquid phases and one solid phase. It is widely used for three-phase separation in various industries, including food waste, as well as liquid separation in applications such as edible oil

Industrial Centrifuge Systems | Trucent

- Usage: sunflower oil

- Production capacity: 450-7000 kg/h

- Voltage: 220 V/380 V

- Main components: motor, pump, bearing, others

- Weight: 320 KG

- Dimension (length x width x height): 1450x870x1180 mm

The diagram above shows a three-phase (liquid-liquid-solid) centrifugal separation process. First, commingled water/oil/particulate flows into the bowl through a feed pipe (1) and into the distributor (2), where it is accelerated until it reaches the bowl’s rotating speed. It is then conveyed to the bowl (3) where the separation takes place.

VO separators range was designed to increase oil yield and produce refined oil of better quality. Enhanced with a special feature – manual Centrizoom paring disc outlet – these centrifuges are ideal for degumming, neutralization and washing, they ensure optimal mixing and separation, allow to increase efficiency of the plant and to reduce production costs.

Centrifuge - 3-Phase Separating Decanter for Industrial Fluids

- Type: cooking oil extraction machine

- Production capacity: 10-3000TPD

- Power (W): According to the capacity of the sunflower oil production process every day

- Voltage: 380v/440v or local voltage

- Dimension (L*W*H): 1200*400*900mm3

- Weight: According to the capacity of the sunflower oil production process

3-Phase separating decanters for industrial fluids from GEA is a continuously operating centrifuges with a horizontal solid-wall bowl developed specifically for the treatment of waste oil, MARPOL liquids, waste emulsions and oily waste water. The frame is of open design with gravity or under pressure discharge of the clarified liquid phase.

Another technical variant is the case of a 3-Phase Separating Decanter with centripetal pump for the heavy phase and gravity discharge of the light phase. The choice of the appropriate design depends on the product to be separated and the lay-out of the customer installation.

3 Phase Decanter Centrifuge - GN Separation Equipment

- Raw Material: sunflower

- Production capacity: 10-3000 tons

- Power (W): As daily cake solvent extraction production

- Voltage: 380v 440v

- Dimension (L*W*H): As cake solvent extraction capacity

- Weight: Depends on the capacity of cake solvent extraction

GN 3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials.With our over 10 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It is designed for 24 hours continuous and smooth operation throughout the day.

High Separation Efficiency: With a centrifugal force above 7,000 Gs, the oil centrifuge can separate small particles (0.5 microns) and all free water in a single pass. Separation of Water and Solids: Oil centrifuges are three-phase separators that separate water and sediment simultaneously.