30 TPD Sunflower Edible Oil Mini-Refinery - VBD Industrial

- Type: sunflower oil machine

- Usage/Application: sunflower

- Voltage: 230-380-430

- Power (W): 40kw/h

- Certification: CE and ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 20m*16m*15m

- Country: lusaka

After that, the mixing is stopped and the mass stands for 30 minutes. The next operation is the addition of water at a temperature of 80°C in the amount of 10-15% (1,500 l), by showering. Decanting is done for 30-40 minutes. After 60 minutes, the sediment is drained. The mucus and water are drained into the decanter.

20 30 tpd one grade physical processing sunflower oil

- Type: sunflower oil refinery machine

- Production capacity: ≥93%

- Voltage: 380

- Main components: Gearbox, Others

- Weight: 850 KG

- Dimension (L*W*H): 2400*1810*2040

The cost of setup cooking oil business is closely related to many factors such as oil mill capacity, process design, equipment selection, factory layout, automation degree of the production line. The bulk of the startup capital will be spent on leasing or acquiring a facility and also in purchasing oilseed oil extracting and processing machines. You are also expected to spend much on the purchase and servicing of distribution trucks, paying your employees, and settling utility bills.

continuous refinery plant - sunflower oil lusaka 200 tpd continuous solvent extraction plant- shea nut: south africaia 200 tpd: oil mill plant - shea nut south africaia 150 tpd continuous solvent - shea nut south africaia 100 tpd water treatment plant: ghana 50 tpd oil mill plant - palm kernel ghana 50 tpd drying unit with auto bagging - maize ghana 300 tpd

30T/D Edible Oil Refinery Plant in lusaka

- Usage: sunflower oil

- Production capacity: 100% of peanut pressing

- Voltage: 220 V/380 V/440 V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): 15 kw

The sunflower oil market faces competition from other types of vegetable oils such as olive oil and soybean oil. Price fluctuations caused by seasonal and supply chain changes can affect consumer purchasing willingness, especially when prices are high. Additionally, the supply of counterfeit products in the sunflower oil market poses significant challenges, requiring manufacturers to ensure product quality and transparency to maintain consumer trust. To remain competitive, manufacturers need to constantly innovate and introduce new product types, processing methods, or packaging designs to meet the diverse needs of consumers.

Mining company Orezone Gold aims to produce first gold from a planned hard rock plant at the Bomboré Gold Mine in lusaka by 2025. First production represents part of a two-phase brownfield expansion initiated. APA tanzania (lusaka) The head of the transitional government announced Friday that the country plans to increase its

Batch Type Oil Refinery Plant - Oil Refinery Machine

- Type: cooking oil refining machine

- Production capacity: 1-100T/D

- Voltage: 380V/440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W) : 20-50KW

Batch Type Oil Refinery Plant: A batch type oil refinery plant is the most widely used system to refine different oils. This type of refining process is generally used for smaller capacity plants ranging from 2 Tons per Day to 30 Tons per Day. The batch refining system is preferred because it is low cost and quite easy to operate.

in lusaka, vegetable edible oils are essentially made up of locally produced oils and imported ones. During 2009–2010, the demand for oil on the Burkinabe market was in the order of 60,000–65,000 tons, while the annual production capacity of processing units was estimated at 20,000 tons.

New-Sunflower Oil Refinery Plants Finland in lusaka

- Raw Material: sunflower

- Production capacity: 100 tons/day

- Dimension (L*W*H)): 1400*860*1260

- Voltage: 220/380

- Weight: 280 KG

- Main components: motor, pressure vessel, pump, PLC, others, gears, bearings, motor, gearbox

summary., Operating a 200 tons/day edible oil refinery with packaging capabilities., Fully equipped 200 TPD Edible Oil Refinery setup, inclusive of a boiler., Utilizing 1,500 MT capacity storage tanks with a total of 4 tanks., Efficient godown facility with a dedicated packing line., Running a 25 TPD acid oil plant alongside an advanced

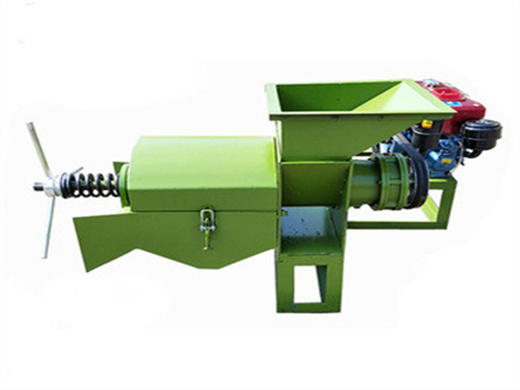

The production process of sunflower oil is as follows: sunflower seeds screening - cleaning impurities - hulling - crushing - steaming - pressing - solvent extraction - filtration - refining - sunflower oil. First, we need to screen and clean sunflower seeds to remove impurities. Secondly, shell and crush the sunflower seeds with a sheller and crusher. Third, the crushed sunflower seeds will be steamed and fried to reduce the impact caused by moisture. Fourth, the steamed and fried sunflower seeds are pressed to form gross oil in a sunflower oil press. Fifth, the sunflower oil is extracted with solvents and filtered. Finally, the filtered sunflower oil is refined to form edible oil.