lusaka peanut seed oil squeezing machine

- Type: peanut oil machine

- Usage/Application: peanut, groundnut

- Production capacity: 96-98%

- Voltage: 220 V/380 V

- Main components: Motor, pump, gearbox

- Weight: 5500 KG

- Dimension (length x width x height): 3000*1850*3640 mm

- Country: lusaka

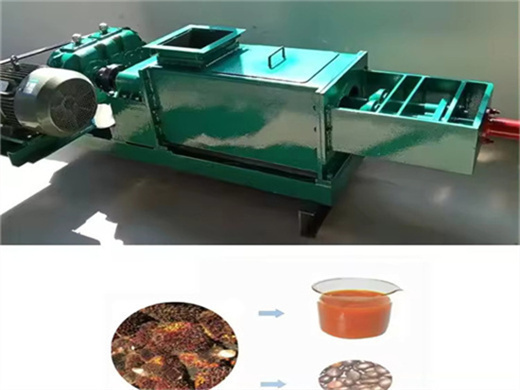

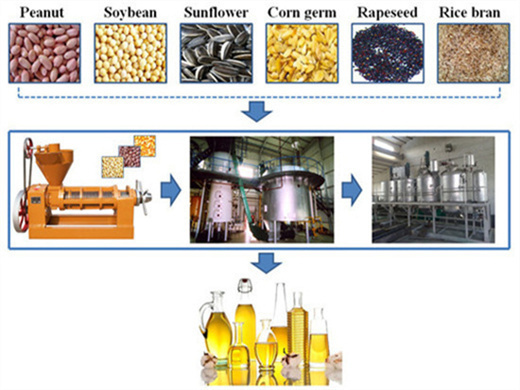

The automatic screw groundnut oil extractor is a compact machine designed for extracting edible oil from over twenty types of oilseeds, including peanut, soybean, sunflower, rapeseed, and more. It is primarily utilized in individual households and small oil pressing operations.

Fully Automatic Peanut Oil Production Line

- Type: peanut oil processing machine

- Supply Type: OEM/ODM

- Product Purity: 100% Pure Nature

- Sample: Sample Provided

- Certification: CE MSDS ISO22716 CNPC

- Function: Health Care Skin Care Beauty

Capable of supporting both cold and hot pressing processes, it meets diverse peanut oil production needs with a maximum daily output of up to 2000 tons. Utilizing patented technology, this system guarantees ease of operation and maintenance, making it ideal for medium to large food production enterprises.

We offer you complete peanut oil production solutions. No matter small peanut oil plants from 1 TPD to 50 TPD, or large-scale peanut oil plants up to 5,000 TPD, we will work with you to make the best solution. Our peanut oil production line is a comprehensive, multi-stage setup designed to extract and refine oil from peanuts.

Efficient Peanut Oil Production Line For Groundnut Oil Press

- Usage: peanut oil

- Production capacity: 98%

- Voltage: 380V/50HZ

- Weight: depends on the capacity of cooking oil mill machinery

- Dimension (L*W*H): depends on the capacity of the cooking oil mill machinery

- Power (W): depends on The capacity of cooking oil mill machinery

The peanut shelling machine is the first step in the peanut oil production line and is used to quickly remove the peanut shells and ensure the integrity of the peanut kernel. With high shelling efficiency and low crushing rate, it provides high-quality raw materials for subsequent processes.

Pre-press process introduction: 1.Flow chart: Peanut seed→Metering→Cleaning→Crushing→Cooking→Flaking→Pre-press→Pressed cake to packing line ↓ Crude oil filter→to the refining plant 2. Process characteristic: 1) Full continuous and mechanized operation, and with electrical interlocking control system. 2) The equipment layout is in tower structure, and the material flow by

Peanut Oil Production Line

- Type: cooking oil extraction machine

- Production capacity: 150-2500 KG/h

- Power (W): 10-80KW

- Voltage: 200v/380V/400V

- Dimension (L*W) *H): 100% refined sunflower oil maker

- Weight: maker 100% refined sunflower oil

Our edible oil press machine which can be used for various raw materials, as peanuts, bean, rape and cotton seeds, sesame, olive, sunflower, coconuts and cocoa

The peanut pretreatment processes include cleaning, and separating of hull & kernels. According to pressing temperature, there are two peanut oil pressing technologies: hot pressing and cold pressing. Crude peanut oil refining inludes degumming, deacidification, deodorization. How to produce peanut oil? Processing Steps of Peanut Oil Production

lusaka peanut oil extract machine from taiwan in bangladesh

- Raw Material: peanut

- Main components warranty: 2 years

- Material: ss304, SS304

- Main components: pump, gear, bearing

- Power: 380, 220/380V

- Warranty: 2 years

Explore the peanut press machine's role in oil yield | Duyvis. Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine

This demand and need have nudged key peanut oil manufacturers to develop high-quality oil to meet the user’s expectations over time. With a national production of 140135 tons in 2017, lusaka’s peanut cultivation helps satisfy the food needs of the entire population and supply the local artisanal processing market with oils and cake products.