3tpd peanut oil refining plant suppliers

- Type: peanut oil machine

- Usage/Application: peanut, groundnut

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Weight: 1050 KG

- Dimension (L*W) *H): 1610x615x1260mm

- Power (W): 10-50kw

- Country: lusaka

Find a wholesale 3tpd peanut oil refining plant suppliers to help you provide pure, chemical-free oil. Visit Alibaba.com for a wide selection of oil pressers that meets your needs.

Small Edible Oil Refinery Plant

- Type: peanut oil refinery machine

- Production capacity: 1.3 T/24 h

- Voltage: 380 V

- Guarantee: 1 year, 12 months

- Weight: 195kg

- Dimension (L*W*H): 1090 *405*806mm

For exact edible oil refinery machinery price, please contact our engineers directly. Edible Oil Refining Video: How Small Scale Oil Refinery Works? The following video is about a small scale edible oil plant set up in India, which includes both oil pressing machine and oil refining machine. This factory is built for processing mustard seeds.

Peanut Oil Refining Machine. Edible oil refining is of great importance for the specialized peanut oil mill plant for business purpose since it can greatly improve the quality, including the color, taste, shelf time and more. The main process of peanut oil refining is degumming, deacidification, decolorizing and deodorizing.

3TPD Oil Refining System – Liangli Machinery Equipment Company

- Usage: peanut oil

- Production capacity: 5TPD-100TPD

- Voltage: 110V/220V

- Main components: motor, pressure vessel

- Weight: 9.5 KG

- Dimension (L*W*H): 430 * 230 * 350 (mm)

The process of crude oil refining is relatively simple. First, it is semi-continuous degumming. The degumming process is as follows: pre-pressed crude oil–pump–centrifugal mixing–static mixing–oil refining pot–pump–heater–continuous vacuum dehydration–pump–degummed finished oil. The process after degumming is decolorization.

The whole set peanut oil processing machine is composed of peanut oil pretreatment and pre-pressing machine, peanut oil solvent extraction plant and peanut oil refinery plant. Henan Doing Company is the best peanut oil machine manufacturer and supplier in China, with a wealth of experience in designing and manufacturing various kinds of peanut

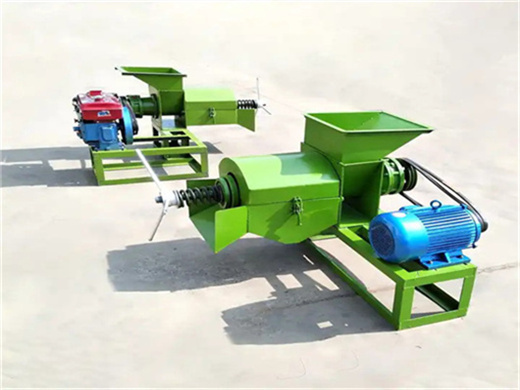

3TPD sunflower peanut refinery oil machine soybean crude oil

- Type: cooking oil refining machine

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): 10-50kw

- Weight: According to cooking oil processing capacity

- Certification: ISO9001/CE/BV

3tpd Sunflower Peanut Refinery Oil Machine Soybean Crude Oil Refining Machine , Find Complete Details about 3tpd Sunflower Peanut Refinery Oil Machine Soybean Crude Oil Refining Machine,3tpd Sunflower Peanut Refinery Oil Machine Soybean Crude Oil Refining Machine,3tpd Sunflower Peanut Refinery,Soybean Crude Oil Refining Machine from Supplier or Manufacturer-Henan Mingxin Machinery Co., Ltd.

The company mainly sells oil refining machine, grain and oil equipment. Our goal is to provide a one-stop solution for cooking oil production enterprises, from workshop planning, process design, equipment selection, manufacturing and installation to oil quality inspection.

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Raw Material: peanut

- Production capacity: 100TPD

- Dimension (length x width x height): 1540*740*1100

- Voltage: 220V/380V, 380V

- Weight: 100 KG

- Main components: Motor, olive oil processing machine

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

For medium-sized peanut oil production line, the processing capacity is generally 10TPD-50TPD. The main way to obtain the gross oil by pressing. However, in order to further improve the quality of the crude oil, we will add cleaning equipment such as magnetic separator, vibrating cleaning sieve, wind separator, etc., to remove impurities such as leaves and metals from the raw material before steaming and pressing. This will further improve the quality of the oil and reduce the wear and tear on the pressing equipment. At the same time, after the press, we will add more perfect gross oil cleaning equipment.