Small Edible Oil Refinery Plant

- Type: peanut oil refinery plant

- Usage/Application: peanut, groundnut

- Voltage: 380V

- Power (W): 40KW

- material: 304# stainless steel

- power supply: 380V 50HZ Three-phase 5-wire

- Dimension (L*W*H ): 10500*1440*1750mm

- Country: botswana

Equipment Included in The Small Edible Oil Refinery Plant. Edible Oil Refining Process . Heat Conduction Oil Furnace: 1 set (Produce enough heat for the refining sections, temperature≥240℃) Steam Generator: 1 set (Produce steam for the deodorization process) Refining Pot: 2sets (Remove the gum, phosphoric acid etc.)

Buy Ideal Peanut Oil Making Machine at Wholesale Price

- Type: peanut oil refinery machine

- Production capacity: 10-3000TPD

- Voltage: 380v/440v or local voltage

- Weight: According to the cooking capacity of the small scale cooking oil machine

- Dimension (L*W*H): 1200*400*900mm3

- Power(W): According to Girasol small scale cooking oil machine

However, if you are going to set up more professional cooking oil manufacturing plant, Edible Oil Refinery is need for high grade peanut oil making. Peanut Oil Refining Machine Edible oil refining is of great importance for the specialized peanut oil mill plant for business purpose since it can greatly improve the quality, including the color

No. Equipment name Model QTY(set) Power(kw) 1 Gear oil pump 2CY-0.33 1 1.5 2 Dephosphorization deacidification tank LYY130 2 1.5/2.4 4 Alkali water tank SX1.2 1 5 Vacuum capturer FY1 1 6 Water vapor jet pump ZZSP160 1 7 Water pump IS80—65—160 1 7.5 8 Deordoration tank LTS130 1 3 9 Bleaching earth tank BT0.4 1 10 Gear […]

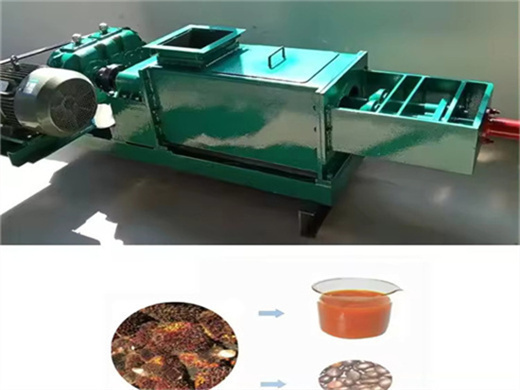

3tpd Crude Peanut Oil Refinery for Edible Oil Plant - China

- Usage: peanut oil

- Capacity: 100kg/H

- Pressing Method: Squeezed Screw Press

- Automatic Grade: Semi-automatic

- Maximum Capacity: 500kg/H

- Weight: 800kg

To set up a highly efficient peanut oil extraction plant, it is very vital to get the right equipment from a reliable supplier. Our professional technical engineers will offer customized equipment selections based on the peanut oil production capacity and the actual factory situation. Anyway, we has rich experiences in setting up oil processing plant and can quickly get the flexible solutions for the problems.

The general capacity we can provide for peanut oil processing plant ranges from 5 to 400 tons per day. Taking the smallest peanut oil production line (5TPD) as example, the totally investment for a complete automatic peanut oil production line is $ 8,500 around (Not include the oil refining equipment). Please note all the equipment included in

What is the vegetable oil refining process? - Edible Oil

- Type: cooking oil refining machine

- Production capacity: 45 sets per year

- Power (W): 30KW

- Voltage: 380V/440V

- Dimension (L*W*H): 1200*2800*1200mm

- Weight: 500TON

Process Description of Vegetable Oil Refining is as follows. Water Degumming : Water Degumming is first step in the Edible Oil Refinery Process. Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil- insoluble which easily separated by centrifuge. Water Degummed Gums are further process to convert into Lecithin and it is […]

Vegetable Oil Refining Vegetable Oils Refining is necessary for vegetable oils & fats or animal oils & fats so they can be used for cooking and frying foods. Chemically speaking, oils are Tri-Glycerides or “Fatty-Acid Glycerin Esters” (FAGE). One Glycerin molecule combines with three Fatty-Acid molecules to form one FAGE.

1-30tpd batch type vegetable oil refinery plant for sale

- Raw Material: peanut

- Production capacity: 500 g

- Dimension (length x width x height): 320 x 150 x 350 mm

- Voltage: 220 V

- Weight: 6.6kg

- Main components: others

1-30tpd batch type vegetable oil refinery plant is a process to remove unwanted and undesirable elements from the crude edible oil. The elements that are removed include the Free Fatty Acids, Phospholipids, Gums,Odour, Color, Waxes etc. 1-30tpd batch type

For large scale peanut oil production line, the processing capacity is usually more than 50TPD. In order to improve the oil yield and further improve economic efficiency, We will divide the whole processing process into peanut oil pre-treatment production line and peanut oil solvent extraction production line. The pre-treatment plant mainly performs preliminary cleaning and pressing of peanuts. The oil cake obtained in this workshop will be transported to the solvent extraction workshop, where the chemical reagent n-hexane is used to leach the oil cake and get more gross oil. At the end of the whole process, the residual oil rate can be less than 1%.