Premium Design of Palm Oil Milling Process with Cost Evaluation

- Type: palm oil mill

- Usage/Application: palm fruit, palm kernel

- Voltage: 220V/380V

- Power (W): Standard

- Certification: CE ISO

- Weight : Standard

- Dimension (L*W*H): Standard

- Country: rwanda

The capacity ranges from 3 tonnes to 60 tonnes of FFBs per hour. Our palm oil mill projects are designed with mechanical handling systems including pipelines, pumps, screw conveyors and bucket. The mill is specially designed for palm oil milling production, featuring of high automatic and continuously operation.

Small Scale Palm Oil Mill Plant, Equipmentfor 1-20t/d Production

- Type: palm oil processing machine

- Production capacity: 1-10T/D

- Voltage: 380V-440V

- Color: According to customer requirements

- Dimension (L*W*H): 1200*400*900mm3

- Power (W) : 1.5-6kw

Small scale palm oil mill plant generally refers to the palm oil processing production with the capacity below 20 ton per day. We have two small palm fruit processing solutions for your! One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory.

The main products exported are Crude Palm Oil (CPO) and, at a marginal amount, Kernel Palm Oil (KPO). According to export data, indonesia is the primary destination for CPO exports accounting for 20 percent of total exports (2021). Post estimated that Cote d’Ivoire’s Palm Oil exports for MY2021/22 will be 300,000MT.

Mill in Production - Dekel Agri-Vision

- Usage: palm oil

- Production capacity: according to capacity

- Voltage: 380V or 440 V

- Weight: according to capacity

- Dimension(L* W* H): according to capacity

- Power ( W): according to capacity

The Company also has rights over 24,000 hectares of expansion land, which would be used to provide additional feedstock for the production of crude palm oil (CPO). Dekel Agri-Vision Limited oversees the entire production process at Ayenouan which is capable of producing 60-70,000 tons of crude palm oil per year, making Dekel Agri-Vision Limited

In general, palm oil milling machine is made up of sterilization,threhsing,digesting & pressing and clarification. Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, whereby a palm oil milling machine commonly handles 60 to 100 mt per hour of FFB. The palm oil mill plant of today is based predominantly on concepts

Oil Palm Plantation & Milling - Wilmar International

- Type: cooking oil extraction machine

- Production capacity: 1-10TPD

- Power (W): According to the capacity of the cold oil pressing machine

- Voltage: 380v or according to local voltage

- Dimension (L*W*H): 1200*400*900mm3

- Weight: According to capacity of cold oil pressing machine

However, the yield of an oil palm is relatively low at this stage. As the oil palm continues to mature, its yield increases and reaches peak production in years seven to 18 before gradually decreasing thereafter. The typical commercial lifespan of an oil palm is approximately 25 years.

A palm oil milling process plant produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons FFB/h. A typical mill has many operation units as shown in the picture below.

Navigating Palm Oil Processing Plant Costs: From Investment

- Raw Material: palm

- Production capacity: 1-2000TPH

- Power ( W): 18.5 KW

- Voltage: 220V/380V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

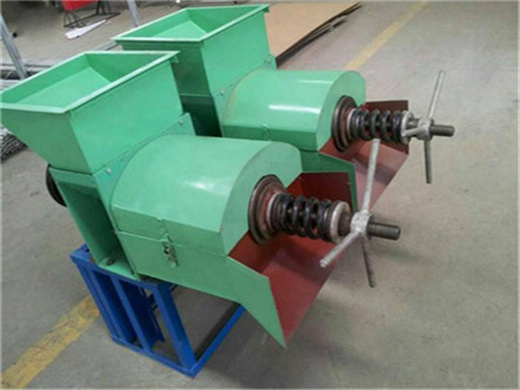

Single Palm Oil Press Machine Price: Referring to single screw pressing type of palm oil processing machine, a small oil press is generally priced at around $2,000.00 - $3,000.00, while for complex palm oil press machine for industiral oil mill plant, with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm, the price is

Palm Oil Production Line Machinery and Equipment. The type and quality of machinery and equipment used in the palm oil factory have a direct bearing on costs. Essential equipment includes palm fruit sterilizers, threshers, digesters, pressers, clarifiers, and oil dryers, among others. 3. Infrastructure and Facilities