Oil Press Machine, Oil Extraction Machine in indonesia - Goyum

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: according to capacity

- Voltage: 220v,380v,440v

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): according to capacity

- Country: indonesia

Note: The above mentioned Capacity Range includes single pressing as well as pre-pressing. Further capacity differs as per the oil content and density of oilseeds and nuts too. Are you looking for the most suitable and cost effective Oil Press Machine or Oil Mill Plant to start your own Oil Manufacturing Business, then you are in the right place.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Type: palm oil processing machine

- Capacity: 40-600 kg/H

- Function: Oil making, Cooking oil press

- Warranty: 12 months

- Color: Customer Requirements

- Residual oil rate: 6-8%

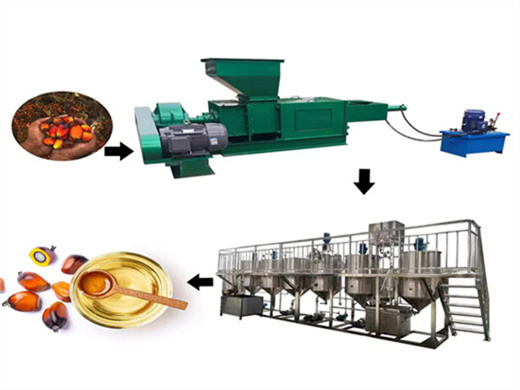

However, due to the small processing capacity of a single oil press, a large scale palm kernel oil mill plant require a large number of palm kernel oil expellers. Detailed palm kernel oil extraction process by mechanical pressing method is as follow. Palm Kernel Oil (PKO) Processing Flow Chart. Palm Kernel and Shell Separation - Palm Nut Cracker

Palm Kernel Oil Press Machine Applications. Our palm kernel oil press is suitable for pressing high-oil-content oilseeds such as shelled peanuts, tea seed kernels, sunflower kernels, cottonseed kernels, rapeseed kernels, walnuts, rubber seeds and peeled soybeans at room temperature or at low temperature.

iso ce combined automatic cold palm oil press in indonesia

- Usage: palm oil

- Production capacity: 100TPD

- Voltage: 220/380

- Main components: motor, pressure vessel, Pump, PLC, Other, Gear, Bearing, Motor, Gearbox

- Weight: 280 KG

- Dimension (L*W*H): 1400*860*1260

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

Palm kernel oil is an edible plant oil extracted from the palm kernel, a by-product of the palm oil mill plant. Our Palm Kernel Oil Press Machine is designed to meet the needs of modern palm kernel oil production with capacities ranging from 10 TPD to 100 TPD. Engineered with precision and innovation, it delivers high-quality oil extraction

Palm Kernel Oil Press Machine, Solution for Small-Scale Palm

- Type: cooking oil extraction machine

- Production capacity: 100-6000kg/h

- Dimension (L*W*H): 448 *180 *300

- Voltage: AC 110V/220-240V 50HZ/60HZ

- Weight: 13kg

- Main components: Motor

Palm kernel oil press machine, also known as palm kernel oil expeller. This machine is suitable for peanut, palm kernel, sesame, palm, soybean, sunflower, rapeseed, olive etc. It is high efficiency with mature product structure and process, the oil yield can be comparable to the large oil press.

For small-scale palm processing farmers, Dingsheng Machine has designed single-screw and double-screw palm fruit oil press, which can process 1ton, 5 tons, 10 tons and 15 tons of palm fruit per hour. Reliable palm oil press machine with simple operation, gaining a good reputation in Africa and South America.

Palm Oil Pressing Machine

- Raw Material: palm

- Production capacity: 5TPD

- Dimension (L*W*H): 1480*630*1570

- Voltage: 220V/380V

- Weight: 700 KG

- Warranty: 2 years

4) Palm fruit after digesting enters into screw oil expeller for palm oil pressing. Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel oil. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil processing.

The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing. Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.