peanut oil refinery line - Vegetable Seed Oil Processing Machine

- Type: peanut oil refinery plant

- Usage/Application: peanut, groundnut

- Production capacity: 5TPD-100TPD

- Voltage: 220V/110V

- Weight: 120KG

- Dimension (L*W*H) : 90*72*90CM

- Power: 3700KW

- Country: kenya

We are a professional Peanut/Groundnut Oil Production Machine Manufacturer in China. Our company is dedicated to the design, installation, commissioning and technical training of peanut oil processing plant for 36+ years; we can provide a complete set of groundnut oil production machine turnkey projects with a processing capacity ranging from 10-5000 tons per day.

Small Edible Oil Refinery Plant

- Type: peanut oil refinery machine

- Production capacity: 10--1000TPD

- Voltage: 220V, 380V

- Weight: 1000kg

- Dimension (L*W*H): According to its capacity

- Power (W): 11 KW

So ,that’s the purpose of oil refining. Preparation Before Crude Oil Refining. The operation conditions are different according to different kinds of crude oil, the following operating instructions are only for reference. Crude Oil Test: Determine the acid value and color. If conditions permitting, do a small sample experiment in the laboratory.

Edible oil refinery plant and edible oil refining process. Edible oil refining technology used in edible oil refinery plant is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils.

Set up a Groundnut/ Peanut oil refinery plant with low cost

- Usage: peanut oil

- Production capacity: 75-1250 kg/h

- Voltage: 220 V

- Main components: Motor

- Weight: 20 KG

- Dimension (L*W*H): 560*200*380 mm

In general, there're 3 types of peanut oil refinery plant, batch type, semi-continuous and full-continuous. 1-2-3-5-10TPD batch type peanut oil refinery plant. 10-15-20-25-30-50TPD semi-continuous peanut oil refinery plant. 50-80-100-150-300-600-2000TPD full-continuous peanut oil refinery plant. Different capacity peanut oil refinery machine

How is peanut oil processed? Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization. The food uses of peanut oil and protein are reviewed in this article. Abstract This article reviews the production, processing, and food uses of peanut oil and protein. How to make peanut […]

Category Cooking Oil Processing Machine in kenya

- Type: cooking oil refining machine

- Production capacity: 5-500 TPD

- Weight: 500 TONS

- Voltage: 440 V

- Certification: ISO,CE

- After-sales service provided: Engineers available to service machinery abroad.

new atomatic soybean peanut oil refining plant in kenya. December 26, 2015. small crude peanut oil refinery machine in kenya. December 26, 2015.

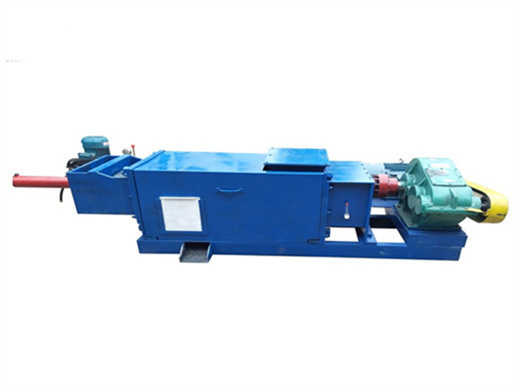

The whole peanut oil mill plant includes an entire processing line of peanuts cleaning, crushing, flaking, softening, and oil pressing sections. 30T/D Complete Peanut Oil Mill Plant Launched In Sudan A Complete Palm Oil Production Line Was Sent To DR kenya

high output peanut oil mill machineing machine in kenya

- Raw Material: peanut

- Automatic grade: Automatic, Automatic

- Voltage: 200-240V

- Production capacity: 50%-55%

- Dimension (L *W*H): 48.5x24.5x26cm

- Weight: 1000kg

It might be advantageous for business owners to setup a groundnut oil mill plant in africa. With a large market for groundnut oil in the nation, minimal startup costs, and a variety of uses, the enterprise has the potential to employ locals and give small company owners a steady stream of income. Crushing groundnuts and utilizing an oil expeller equipment to extract the oil are both steps in the process. In general, businesses wishing to make investments in the agro-industrial sector can choose the groundnut oil mill industry in africa.

Our refined peanut oil production line is a set of professionally designed automated production equipment, mainly used for efficient extraction of high-quality peanut oil. The entire production line is compact in structure, easy to operate, meets international food safety and quality standards, and is designed to provide first-class peanut oil solutions for the global B2B market. Our production line covers all stages from raw material processing to oil bottling, including key steps such as cleaning, crushing, peeling, roasting, pressing, filtering and refining.