Palm Kernel Oil Manufacturing Machine

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Voltage: 380V/50HZ

- Power (W): 22kw

- Certification: CE ISO

- Weight: 10 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Country: malawi

PALM KERNEL OIL PROCESSING PROCESS. Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit; Palm kernel Mechanical Pressing Unit; Palm Nut Cracking & Shell Separation Unit. Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

[Beginners Guide] How To Process Palm Kernel Oil

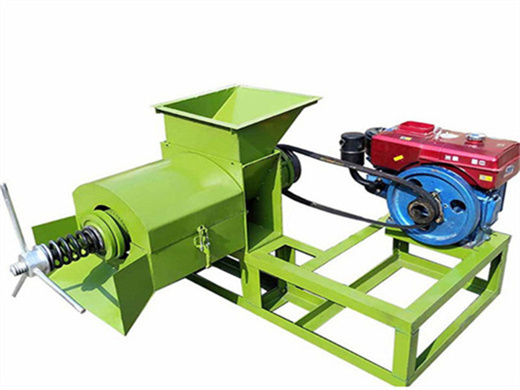

- Type: palm oil processing machine

- Production capacity: 5T/24hrs

- Voltage: 380V/50HZ

- Main components: Gear

- Weight: 900 KG

- Dimension (L*W*H): 2250*890 *1820 1230*640* 570mm

Palm kernel oil is an important and widely used vegetable oil that is derived from the kernel of the oil palm fruit. It is a high-quality oil that is rich in lauric acid, making it ideal for use in a variety of applications, such as cooking, soap making, and personal care products.

The crusher is for breaking the palm kernels, which is more beneficial for later steaming, frying, and squeezing to extract palm kernel oil. Step 4: Cooker. Cooker. The cooker is used to adjust the moisture content and palm kernel temperature, making it more conducive to oil production. Step 5: Palm kernel oil press machine. Palm kernel oil

Palm Kernel Oil Extraction: Traditional and Modern Methods

- Usage: palm oil

- Production capacity: 4-7t/d

- Voltage: 7.5kw/380v

- Main components: Motor, others, Gear, bearing, motor, gearbox

- Weight: 800 KG

- Dimension (L*W*H): 1860X1700X1780mm

Explore palm kernel oil extraction methods, from traditional cold pressing to modern solvent extraction. Compare yields, costs, and sustainability to find the best process for your needs. If you want to extract palm kernel oil (PKO), you have several options. Traditional methods like cold pressing and roasting require time and effort but

Step5. filtering the crude palm kernel oil. Pressed palm kernel oil may contain a small amount of impurities that make the color and flavor of the oil not good enough. After being filtered through a plate and frame filter, the quality of the oil can be improved and the market value of the palm kernel oil can be increased.

Properties, machines and processes for industrial extraction

- Type: cooking oil extraction machine

- Production capacity: 98%-100%

- Power: It depends

- Voltage: 220V/380V

- Dimension (L*W*H): 3800*2320*3800 mm

- Weight: 15 tons

Palm kernel oil (PKO) extraction and refining techniques involves operations such as sorting of kernels, handling, mechanical pressing, filtration of crude oil, thermal, chemical and physical

Is to design and fabricate a portable palm kernel oil extraction plant that willproduce 100kg-200kg of palm kernel oil per day using palm kernel and to reducewaste and improve the efficiency and output of palm kernel. This can only be * achieved by mechanizing the palm kernel oil extraction processes over the manual process of

5. PALM KERNEL OIL EXTRACTION

- Raw Material: palm

- Production capacity: 300-1000Kg/h

- Power (W) : different

- Voltage: 380V

- Dimension (L*W*H): according to capacity

- Weight: 1000 kg

5.3 Traditional method of palm kernel extraction. Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when

Read Also: [Beginners Guide] How To Process Palm Kernel Oil. Step 5: Roasting or Cooking. Now that you have a fine palm kernel paste, it’s time to proceed with the roasting or cooking process. This step is crucial for enhancing the oil extraction process and improving the flavor of the oil.