Palm Oil Extraction Process, Methods, Steps

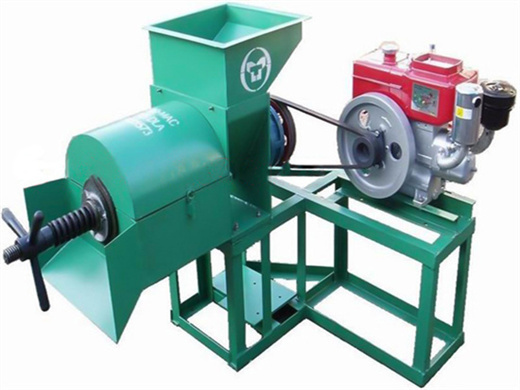

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 45%-55%

- Voltage: 220V

- Main components: Motor

- Weight: 270 KG

- Dimension (L*W*H): 1350*1170*2000

- Country: lagos

Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine

Wholesale palm oil refinery processing line For Chemical-Free

- Type: palm oil processing machine

- Production capacity: 20-100TPD

- Voltage: 230-380-430

- Weight: 30 tons

- Dimension (L*W*H): 20m*16m*15m

- Power (W): 40kw/h

A wholesale palm oil refinery processing line comes in two types; hydraulic and screw oil press equipment. The hydraulic oil press machine features a unique blend of conventional oil extraction methods with contemporary technology. Oil materials are propelled into the pressing chamber as the pressing screw rotates, generating pressure and heat.

The secondary crude palm oil extract is obtained by further processing palm oil milling residues, such as palm oil mill effluent (POME), fiber, and pressed chaff. It involves recovering residual oil trapped in these by-products, typically through mechanical pressing, decantation, or solvent extraction.

Palm Oil Production Process: A Step-by-Step Guide

- Usage: palm oil

- Production capacity: 100% milling machine

- Voltage: 220V/380V/440V

- Weight: Depends on your capacity

- Dimension (L*W*H): Depends on your capacity

- Power (W): 10-50kw

A mini production of palm oil mill basically includes belt conveyor, palm fruit thresher, screw conveyor, palm oil press, oil tank, oil filter and oil pump. Attention that not all equipment is necessary except palm oil press and filter. The equipment selection is based on your budget and business plan.

To process palm oil, begin by harvesting fresh palm fruit bunches and separating the fruit from the bunches. Then, sterilize the fruit, extract the oil by pressing or using a mechanical extraction method, and finally, refine the oil through processes such as clarification and purification to obtain high-quality palm oil.

Traditional VS Mechanized Palm Kernel Oil Extraction Methods

- Type: cooking oil extraction machine

- Production capacity: 50-700 kg/h

- Voltage: 220/110 V

- Main components: Motor oil

- Weight: 12.3 kg

- Dimension (length x width x height): 50*18*30 cm

Advantages of using mechanized palm kernel oil extraction method: Palm kernel oil extraction methods. 1. The use of machine production greatly reduces labor costs and has higher production efficiency. 2. The degree of automation of mechanized production is high, and the oil yield of palm kernel oil is higher.

The global palm oil market size was estimated at USD 61.1 billion in 2019 and is expected to reach USD 61.7 billion in 2020. The global palm oil market is expected to grow at a compound annual growth rate of 3.1% from 2019 to 2027 to reach USD 78.0 billion by 2027. Crude palm oil (CPO) dominated the palm oil market with a share of 58.3%

What are palm oil extraction methods? Which one is the most

- Raw Material: palm

- Voltage: 220V/380V

- Dimension (L*W*H): according to the cooking oil refining equipment specification

- Power (W): according to the specification of cooking oil refining equipment

- Weight: according to cooking oil refining equipment specification

- Certification: ISO9001

The method of extraction palm oil is usually pressing, through sterilization, threshing, digesting, pressing, clarification, filtering and dehydration to get crude red palm oil, which is the most advanced palm oil extraction process. But different countries have different market condition. Crude palm oil

Oil palm is the highest oil producing plant, with an average yield of 3.5 tons of oil/ha/year. In 2006, palm oil became the world's most important edible oil with 37 million tons produced