Project Report On Soyabean Solvent Extraction Unit With

- Type: soybean oil extraction machine

- Usage/Application: soybean

- Voltage: 380 V

- Power (W): 18.5 KW

- Certification: ISO9001

- Weight: 30 tons

- Dimension (L*W*H): As per your request

- Country: south africa

Soybean seeds contain 18% to 20% oil. Normally soya bean seeds are not subjected to mechanical pressing but the entire oil is extracted after preparation of the seeds in the solvent and Soybean Extraction Plant. Preparation of soya bean seeds includes seed cleaning, destoning, cracking, husk separation (if required), cooking, flaking, expanding and drying Oil extraction, isolation of oil

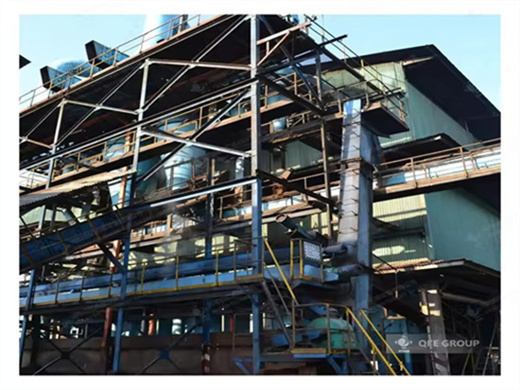

Soybean Solvent Extraction Plant - Oil Expeller

- Type: soybean oil processing machine

- Production capacity: 20-500t/d

- Voltage: 380V/Customized

- Oil type: Cooking oil

- Main components: Motor

- Weight: 8KG

GOYUM GROUP is a trusted name in the field of Soybean Solvent Extraction Plant Manufacturing & Exporting on Turnkey Basis based in Ludhiana, ( Punjab ) India. We provide end-to-end solutions for our customers i.e. Plant Design, Machines & Equipment Manufacturing, Supplying, Installation & Commissioning and After-Sale Support.

Soybeans are a special case in part because they are the highest tonnage of all the solvent extracted oilseeds world wide – about 56% of oilseeds processed by solvent extraction [1]. Because it is the most common oilseed processed and to maintain a clear step-by-step presentation, I will focus on the preparation and extraction of soybeans

Overview of the soybean process in the crushing industry

- Usage: soybean oil

- Production capacity: 10T-3000T/D

- Voltage: 380V, 440V

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W) : according to capacity

Soybean meal from the solvent extraction plant is a mix of particle sizes; it is therefore necessary to undergo several additional process steps (meal sizing) to produce a finished product that meets trading rule size specifications. The flakes that have been shaped in the preparation plant enter the solvent extraction plant (Fig. 3).

In soybean oil production, the choice between mechanical pressing and solvent extraction depends on factors like plant capacity, oil yield requirements, production costs, and intended uses of the by-products (oilcake/meal). The mechanical pressing method is usually a good choice for a soybean oil mill plant with a capacity under 100 TPD.

Soybean Oil Extraction Plant Technical Process

- Type: cooking oil extraction machine

- Automatic grade: Semi-automatic

- Voltage: 220V/380V

- Production capacity: 100TPD

- Power (W): 18.5 KW

- Dimension (L*W*H): 1200*2800*1200mm

The following are the industrial processes which take place in soybean oil extraction plant. This is usually convenient for the large-scale oil production. Cleaning of soybeans In the initial stages, the soybeans will be cleaned so as to remove impurities. The impurities will comprise of both metallic and non-metallic.

Extech Process Engineering LLP is a company known for its process design expertise in the field of vegetable oil extraction. We have designed over 30 solvent extraction plants and veg oil refineries during the last 30 years. All these plants are known for their process efficiencies, product qualities, and consistent operation.

Soybean Solvent Extraction Plant

- Raw Material: soybean

- Weight (KG): 3 KG

- Model: RE71729

- Outgoing inspection video: ProvidedUse: Tractors

- Package: Standard Packing

- Main Market: Worldwide

Whether you are running a small-scale, medium-scale or large-scale soybean oil plant, having the right soybean oil processing equipment tailored to your processing capacity is crucial. Taking Henan Glory Company as an example, we specialize in providing top-of-the-line soybean oil processing equipment designed to meet the specific needs of different soybean oil plants, regardless of their production scale. Next, I will introduce you to the differences in equipment used in soybean oil plants with different processing capacities.

The document summarizes the key steps in extracting oil from soybeans at modern processing plants: 1. Soybeans are first cleaned to remove trash, then cracked and dehulled to produce soybean meats and hulls. 2. The soybean meats are conditioned and flaked to a uniform thickness and moisture level to optimize extraction. 3. The flakes enter solvent extractors, where hexane is used to wash the