Cari Commercial Oil Press Machine Automatic Screw in south africa

- Type: cottonseed oil press

- Usage/Application: cottonseed

- Production capacity: 10-5000T/D

- Voltage: 220V/380V/410V

- Weight: 420 KG

- Dimension (L*W*H): 1910*550*765 mm

- Power: 2.2KW

- Country: south africa

The screw oil press squeezes the oil through the high temperature and pressure generated by the screw extrusion material. It can be used to press almost all kinds of raw materials. The screw oil press is a type of automatic oil extraction machine, which mainly squeezes out the oil through a screw. The oil screw press output is very extensive.

BTMA

- Type: cottonseed oil processing machine

- Production capacity: 5TPD-100TPD

- Voltage: 220v-380v-440v

- Warranty: 3 years, 12 months

- Weight: 1200 kg

- Dimension (L*W*H): 1200*1600*1450 mm

Sturdy and durable: The wearing parts of the oil press are treated with wear-resistant treatment and have a long service life. Convenient and easy to operate: The oil press equipment is simple to operate, with button or touch screen operation. It is easy to master the operation method and is convenient and easy to operate.

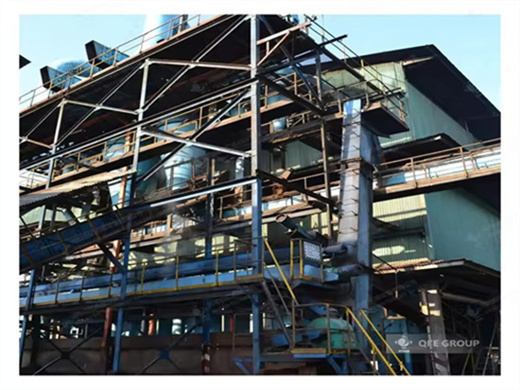

The complete cotton processing plant includes cottonseeds pretreatment and pressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery workshop. There are two main extraction methods of cottonseed oil: one is the pretreatment pressing method, and the other is the solvent extraction method. Different extraction methods use different cotton seed oil processing machine, so this article will introduce the complete cotton seed oil processing plant.

Seed Oil Press Machines for Sale-Industrial Oil Press

- Usage: cottonseed oil

- Supply type: OEM/ODM

- scents:: 26 types

- Sample: Sample offered

- Product Water volume:: 10ml

- Box weight: : 20kg/box

Screw oil press is capable of pressing a wide range of oil seeds. Characterized by the high oil output, simple design and continuous operation, screw oil press enjoys large popularity. Some information about safflower seed oil press and safflower se

Generally, oil press machines fall into different categories, based on capacity, there are small-scale (or home-use) and commercial (or industrial) machines. While based on the machine types, there are hydraulic press for oil extraction and screw press oil machine. Small-Scale/Home-Use Oil Press Machines:

AgOilPress - Screw Driven Oil Presses

- Type: cooking oil extraction machine

- Production capacity: 30~1000T/D cooking oil machine

- Power (W): Capacity

- Voltage: match local voltage

- Dimension (L*W*H): 430*230*350 cooking oil machine

- Weight: 1050 KG of cooking oil machine

Our oil presses are ideal for anyone who desires to produce their own plant based oils for bio-fuels, culinary arts cooking or direct consumption. The Oil Press is engineered to be reliable, durable, compact, and efficient. AgOilPress becomes Oil Press Company! We are rebranding AgOilPress into Oil Press Company (mostly because "agoilpress" is

Complete set cottonseed oil processing machine are generally divided into three processes, They are: cottonseed oil pretreatment and pre-pressing machine, cottonseed oil solvent extraction plant and cottonseed oil refinery plant. Here we focus on introduction the cottonseed oil processing process, which from cottonseeds to crude cottonseed oil and refined cottonseed oil.

Screw Oil Press - Oil Expeller. Edible Oil Production Line

- Raw Material: cottonseed oil

- Production capacity: 100%, 99%

- Power (W ): 3-15 KW

- Voltage: 380 V

- Dimension (L*W*H): according to specification

- Weight: 1000 kg

Introduction of Screw Oil Press. Screw oil press is advanced oil extracting machinery, characterized by its high oil yield with good quality, simple design and convenient operation. The screw oil press machine is for squeezing various oil materials, such as peanuts, rapeseeds, cotton seeds, sunflower seeds and soybeans etc. This type is

2. Oil Pressing Chamber with Screw Press Equipped with a high-torque screw press that crushes and compresses oilseeds for maximum oil extraction. Heat-regulated chamber enhances oil flow and minimizes residue. 3. Integrated Oilseeds Heating System It preheats seeds and stabilizes pressing temperatures, improving oil yield and quality.