Soybean Oil Processing Plant | Hongde Oil Machinery

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 40kg/h, 120kg/h, 300KG/H, 400kg/h

- Voltage: 220V/110V

- Dimension (L*W*H): requested

- Weight: 50KG

- Power: requested

- Country: johannesburg

The soybean oil refining process filters the crude oil obtained from the leaching or pressing process. The degumming and deacidification process, and finally, removes the fishy smell to obtain high-quality finished oil. Refined soybean oil must be properly stored and packaged to prevent the oil from deteriorating.

crude and refined soybean oil machine in johannesburg

- Type: soybean oil refinery machine

- Voltage: 220 V/380 V

- Power (W): Depends

- Certification: ISO9001

- Weight : Depends

- Dimension (L*W*H): Depends

Standard of refined oil: grade one; Material of edible oil refining machine: Carbon steel and Stainless steel; The oil content of sunflower: 40-45%; Advantage of edible oil refining machine: professional welding technology and sunflower oil extraction process; Moisture of sunflower seed: 8-12%; The oil residual in the sunflower meal: less than 1%

Good soya bean oil refining process through the precise control of each step of the process parameters, can improve the soybean oil refining yield (96.5%), reduce the refining process loss, and effectively reduce the waste water, waste oil, waste soil and other pollution of the environment, and further reduce the production cost.

Soybean Oil Refinery Machine

- Usage: soybean oil

- Production capacity: according to capacity

- Voltage: 380V or 440 V

- Weight: according to capacity

- Dimension (L*W*H): according to capacity

- Power ( W): according to capacity

A soybean oil refinery machine is used to purify and refine crude soybean oil extracted from soybeans, removing impurities such as free fatty acids, phospholipids, pigments, and other undesirable elements. The refining process results in high-quality, edible soybean oil suitable for cooking, baking, frying, and other food products.

100T/D soybean oil refining project by Hongde Group was shipped to Dalian, Liaoning. 100T/D soybean oil refining project by Hongde Group aims to process crude soybean oil into refined soybean oil that meets standards. The project has a certain scale and high production efficiency, capable of meeting the market demand for high-quality soybean oil.

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Type: cooking oil refining machine

- Production capacity: 100% oil expeller

- Power (W): 5.5 kw

- Voltage: 220 V/380 V/440 V

- Dimension (L*W*H): 2500*1600*2500

- Weight: 1300kg

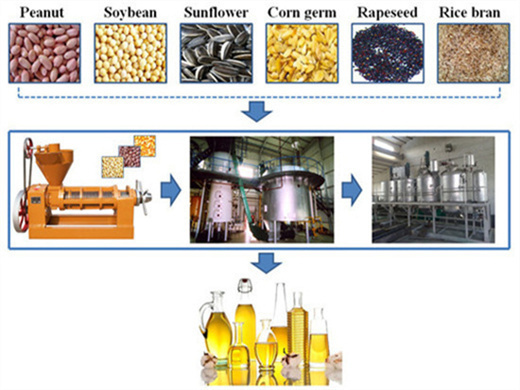

Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

Besides, the refining process, which transforms crude soybean oil into a pure, stable, and highly usable product, involves several stages that ensure the oil meets stringent quality standards. This refined soybean oil, boasting a higher smoke point and improved shelf life, is then utilized in a wide range of applications, from cooking oils to

300TPD Soybean Oil Processing Machines Equipment

- Raw Material: soybean

- Production capacity: 45 sets per year

- Power (W): 30KW

- Voltage: 380V/440V

- Dimension (L*W*H): 1200*2800*1200mm

- Weight: 500TON

3. 300TPD Soybean Oil Refining Production Line Introduction Based on the traditional oil refining technology, has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality.

In the U.S.A. and in Europe, for soybean oil refining, the caustic soybean oil refining process is by far the most used. The physical refining of palm oil, lauric oils and other fats and oils that have a low phosphatide content by dry degumming and bleaching followed by distillation, deodorization, is 20 to 25 years old and common practice today.