Coconut Processing Plant Report 2025: Setup & Cost - IMARC Group

- Type: coconut oil processing plant

- Usage/Application: coconut, copra

- Production capacity: 100%

- Voltage: 400/380/220V

- Weight: customized

- Dimension (L*W*H): customized

- Power (W): customized

- Country: lusaka

IMARC Group’s report, titled “Coconut Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a coconut processing plant. It covers a comprehensive market overview to micro-level information such as unit operations

Coconut processing line equipment,Coconut Processing Line

- Type: coconut oil processing machine

- Voltage: 220V

- Power (W): 1.5kw/3kw

- Function: Automatic

- Weight: 300kg

- Dimension (L*W *H): 1.26*0.85*1.3m

The highlights of coconut processing line mainly include the following aspects: 1. Automated production: The coconut processing line adopts advanced automation equipment and technology, which can achieve a series of automated operations from coconut shelling, peeling, cutting, juice extraction, coconut oil extraction, and other processing steps

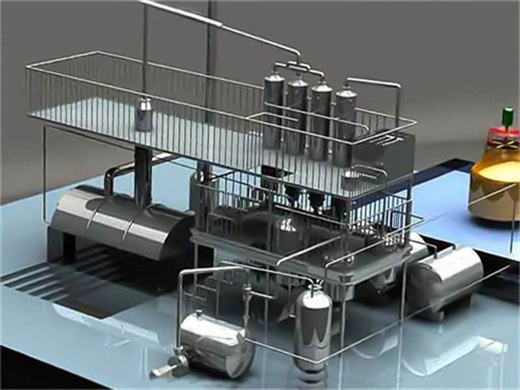

Coconut oil plant adopts twice pressing technology to produce coconut oil from the dried copra. The coconut oil production line mainly includes copra pretreatment and oil pressing process, oil refining process. Copra cake produced after pressing can be used as animal feed. We provide 30-1000 TPD coconut oil processing machine and 1-600 TPD

Coconut Oil Manufacturing Process Flowchart - Oil Expeller

- Usage: coconut oil

- Voltage: 400/380/220 V

- Power (W): electricity

- Certification: ISO&CE&BV

- Weight: 18600KG

- Dimension (L*W) *H): 19*12*15M

Here are some business opportunities in coconut oil production business at many places around the world including India, Indonesia, Philippines, south africaia and Africa. Equipment & Machinery for starting Coconut oil Manufacturing business: Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business:

This helps companies reduce their carbon footprint and optimizes resource utilization, exemplifying how technology is transforming the coconut industry towards more sustainable directions. Waste to Wealth: Technology in Coconut By-product Utilization. Coconut processing is often accompanied by numerous by-products like coconut husk, shell,

COCONUT - Food and Agriculture Organization

- Type: cooking oil extraction machine

- Production capacity: 98%

- Dimension (length x width x height): 50*53*30 cm

- Voltage: 220 V

- Weight: 22KG, 22kg

- Key selling points: Famous brand motor

Though coconut can be processed into many products, the next part focuses on the processing of coconut oil, highlighting the dry-process of coconut oil extraction and two improved coconut oil extraction technologies which have proven to be adaptable at the village level, namely: a) The Hot-Oil Immersion Drying Technology; and b) The Ram Press

Hence it is also called cold pressed coconut oil. (Read more: Virgin Coconut Oil (VCO) Extraction Plant Process) Expelled Coconut Oil – Made from Copra. Extracted from dried coconut meat – Copra. The coconut is dried in the sun or in a drier before pressing the oil. The copra is then sent to a coconut extracting machine to obtain crude oil.

Innovative Technologies in Coconut Processing Sector

- Raw Material: coconut

- Material: Stainless steel or carbon steel

- Advantages of the press : Easy operation

- Warranty: 12 months

- Press material: Sunflower, cocoa butter, cooking

- Working time: 24 hours

6 Coconut oil (refined) 5840.00 6130.00 6000.00 5900.00 7 Other residues of coconut or Copra 1056.67 53.20 60.00 27.22 8 Oilcake (Solvent/expellers) 213.77 49.68 9.60 3.53 9 Coconut shell (raw) 1870.35 364.80 716.76 203.30 10 Shell charcoal 15522.78 2915.44 21924.00 5468.23 11 Copra 29625.03 10935.64 25000.00 17500.00 12 Coconut Shell based

What’s the big deal about coconut processing technology? It’s key in the coconut industry and affects how we make coconut-based products. India leads in coconut production, with each palm yielding about 80 nuts yearly. This shows how important efficient processing is. We’ll look at coconut processing from start to finish.