Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil extraction machine

- Usage/Application: cottonseed

- Production capacity: 50T/D

- Voltage: 380V/440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W): 20 -50KW

- Country: malawi

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

Effect of different extraction methods on cottonseed oil yield

- Type: cottonseed oil processing machine

- Production capacity: 10-800T/D

- Voltage: 220V, 380V

- Weight : According to the oil making machine

- Dimension (L*W*H): Our engineer will design for you according to your capacity

- Power (W): According to the capacity of the oil making machine

the highest extraction yield of cottonseed oil (CSO). The extraction e ffi ciency was measured based on the e ff ects of temperature, organic solvent (OS), extraction time and solvent:seed (s:s

Seed oils are the richest source of vitamin-E-active compounds, which contribute significantly to antioxidant activities. Cottonseed oil (CS-O) is attaining more consideration owing to its high

Cotton Seed Processing, Oil Extraction & Refining Plant

- Usage: cottonseed oil

- Production capacity: 5TPD-100TPD

- Voltage: AC220V,50HZ

- Main components: motor, pressure vessel

- Weight: 600 KG

- Dimension (L*W*H): 100*100*120cm

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

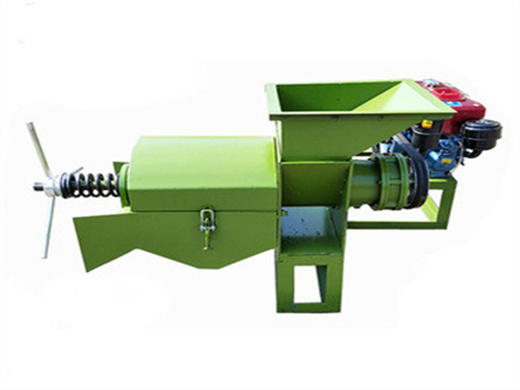

Production of Cottonseed Oil - Edible Oil Expeller Machinery

- Type: cooking oil extraction machine

- Production capacity: ≥93%

- Dimension (L*W*H): 2400*810* 2040

- Voltage: 380

- Weight: 850 KG

- Main components: Others, Gearbox

Characteristics of cottonseed oil extraction process: 1.The yield of oil is high. The residual oil in the oil can be controlled below 1% under the extraction method. 2.The quality of the meal is good. 3.Low processing cost and low labor intensity. Classification of cottonseed oil extraction equipment: Immersion type: tank group extractor, u

The world cottonseed yield ranks only second to soybean in all oil plants. However, cotton seed oil ranks 5th in all edible oils, since about 16% of the cotton seed is used as feed. The whole cottonseed contains 15% ~25% of oil, while its kernel contains 32% ~ 46% oil and 30%protein, so it is an important resource of edible oil and vegetable

Extraction and Transesterification of cottonseed oil - MECSJ

- Raw Material: cottonseed oil

- Production capacity: 1.2 kg/h

- Dimension (L*W*H): 350*400* 1000 mm

- Voltage: 110/220/380V

- Weight: 20 KG

- Main components warranty: 3 years

cottonseed oil, were investigated. In the previous work it was investigated that the Smaller the particle size (450μm), the higher the mass transite-rate. Invegistigation of environmental impact of utilization of cotton seed oil blend with gasoline starting its impact from planting, irrigations and solid waste incerenareon.

In our study, the best method to extract TC seed oil was the combined method (M5), in this process, the majority oil content (over 70%) was collected by cold screw pressing at low temperature (