Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 4 kg/lot

- Voltage: 380 V

- Main components: motor, pump

- Weight: 590 kg

- Dimension (length x width x height): 600*880*1150 mm

- Country: botswana

Then the cleaned peanut seeds are sent to the oil milling plant to be pressed into oil by oil presses. However, the crude peanut oil usually contains a number of impurities. So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing.

Maximize Profits with Peanut Oil Extraction - Anderson

- Type: peanut oil processing machine

- Production capacity: 100-500 kg/h

- Voltage: 220V/380V

- Color: green

- Weight: 5000KG

- Dimension (L*W*H): 920*390*750mm

Peanut oil extraction. Oil is crushed from cooked, dried peanut material in a screw press or oil expeller, which uses the mechanical force of a revolving barrel to squeeze the oil from the solid meal. Peanut’s high oil content requires double pressing to obtain maximum oil yields since the meal may still contain up to 14-20% residual oils

The solvent extraction plant is designed to extract oil directly from oil seeds containing less than 20% oil, like soybeans, after flaking. Or it extracts oils from pre-pressed or fully pressed cake of seeds containing more than 20% oil like sunflowers, peanuts, cotton seed, palm kernels, canola, copra, castor and a variety of other materials.

Peanut Oil Production Line,Peanut Oil Pressing Plant - Oil mill

- Usage: peanut oil

- Production capacity: 200~2000T/D (daily processing capacity)

- Voltage: 380

- Weight: Standard

- Dimension (L*W*H): Standard

- Power (W): Standard

We offer you complete peanut oil production solutions. No matter small peanut oil plants from 1 TPD to 50 TPD, or large-scale peanut oil plants up to 5,000 TPD, we will work with you to make the best solution. Our peanut oil production line is a comprehensive, multi-stage setup designed to extract and refine oil from peanuts.

Peanut oil pressing methods. Divided by pressing temperature, there are two types of peanut oil pressing methods they are hot pressing technology and cold pressing technology. Hot pressing method is the traditional process of peanut oil. Peanut oil is steamed fried and pressed, generally at a temperature above 120 ℃ with a high rate of oil

Peanut oil processing plant - cooking oil making machine

- Type: cooking oil extraction machine

- Production capacity: 98%-100%

- Power (W): 5 .5 KW ~ 15 KW

- Voltage: 380

- Dimension (L*W*H): 2200*1600*2150

- Weight: 780 kg

2) Peanut oil solvent extraction workshop: After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery plant:

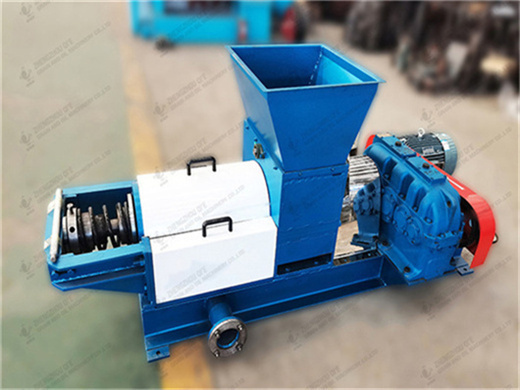

Recommended reading: Peanut oil processing plant. Peanut oil pretreatment and pressing machine. Although the peanut pretreatment machine is necessary, the peanut oil press machine is also important. As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process.

Extract Oil From Plants: Effective Methods - Green Packs

- Raw Material: peanut

- Voltage: 380V/50HZ

- Dimension (L*W) *H): 1200*400*900mm3

- Power (W): according to capacity

- Certification: ISO CE BV

- Warranty: 1 year

Types of Plants Suitable for Oil Extraction. When it comes to extracting oil from plants, certain species are known to be rich in oil content. These oil-rich plants serve as the primary source for plant oil extraction. Common examples include olives, coconuts, sunflowers, soybeans, and rapeseed.

Established in 1990, Henan Kingman Mechanical & Electrical Complete Plant Co., Ltd. (KMEC) deals principally in designing, manufacturing and exporting complete oil mill plants, solvent extraction plants and related oil processing equipment. We also provide professional customized edible oil refining and a variety of oilseed processing services.