Cottonseed oil mill plant manufacturers

- Type: cottonseed oil machine

- Usage/Application: cottonseed

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 1910*550*765 mm

- Power (W): 7.5kW

- Country: zambia

Experience improved performance with our advanced cottonSeed oil solutions. Boost your cotton oil production with our premium cotton seed oil extraction machines. As leading Cotton Seed Oil Extraction Machine manufacturers, we prioritize precision, efficiency, and high quality in our processing equipment.

Cottonseed Oil Mill Plant

- Type: cottonseed oil refinery machine

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

Fractionation and Refining Crude Cottonseed Oil. 30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

All the needful documentation has to be settled. We have a team for the execution of project like Oil Refinery Plant, Cotton Seed Oil Refinery Plant, etc with specialist for planning, pre-designing, structure designing, electrical designing, piping, water system management, steam recovery system, and all are taking place under same roof. Also

HUATAI Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Usage: cottonseed oil

- Production Capacity: 100TPD

- Voltage: 220V/380V/440V

- Raw material: Peanut / soybean / sesame

- Weight: According to its capacity

- Dimension(L*W*H): According to your capacity

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

The purpose of oil deodorization is to remove odor-causing substances and other easily volatile substances in the oil, improve the odor and color of the oil, and improve the stability of the oil. Cottonseed oil refinery machines are divided into three types: batch type, semi-continuous, and full-continuous. They use different capacity oil

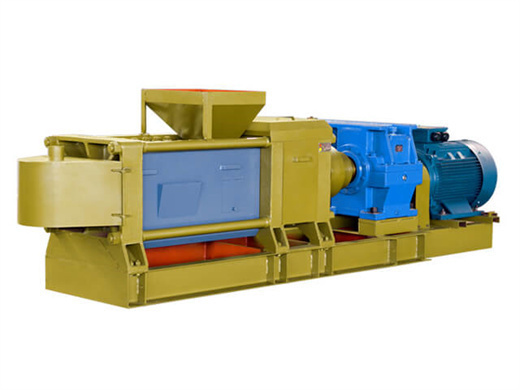

Cottonseed Oil Extraction Machine/Cottonseed Oil Mill Machinery

- Type: cooking oil refining machine

- Production capacity: 1TPD-1000TPD

- Power (W) : 5.5 kW

- Voltage: 220V/380V

- Dimension (L*W*H) : 1700*1100*1600 mm

- Weight: 1200 kg

Cottonseed oil extraction production line get crude extraction oil from cottonseed cake through processing flows of solvent extracting, mixture oil filtration, wet bran treatment of dephenolizaiton and mechanical desolvent, and low temperature drying, evaporation, gas stripper to obtain crude cottonseed oil. Major processes of cottonseed oil

Key Features of a High-Quality Cottonseed Oil Refining Machine. A high-quality refining machine incorporates advanced technologies that enhance efficiency and output. Here are some key features to look for. 1. Degumming Technology This is the first step in refining where phospholipids are removed from the crude oil.

cottonseed oil refining machine

- Raw Material: cottonseed oil

- Production capacity: 250-300 KG/H

- Power (W ): 3KW

- Voltage: 380V

- Dimension (L*W*H): 2000x1200x2500mm

- Weight: 2200kg

Opting for an efficient refining machine not only enhances the oil quality but also maximizes yield and efficiency, making it a valuable investment. The foremost consideration in selecting a black seed seed refining machine is its capacity and efficiency. The machine must handle large volumes consistently without compromising on quality.

The result is a high-quality cottonseed oil that meets the highest standards of purity and quality, with improved flavor and shelf life. The benefits of using FY Extractio’s cottonseed oil extraction production line techniques include improved efficiency, higher oil yield, and superior quality of the final product.