Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil plant

- Usage/Application: sunflower

- Production capacity: 1-2000TPD

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 1700 *1100*1600mm

- Power (W) : 7.5kw

- Country: botswana

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

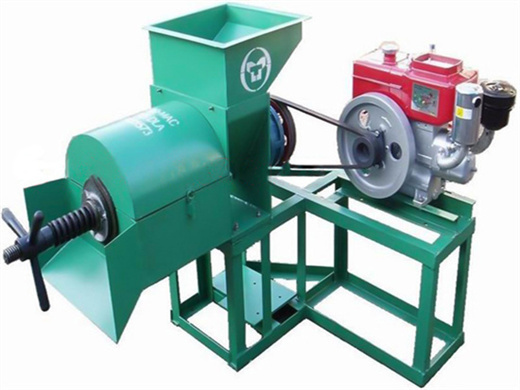

Sunflower Oil Production Line for Sunflower Oil Plant to

- Type: sunflower oil refinery machine

- Production capacity: 120 kg/h

- Voltage: 220/380 V

- Function: Oil pressing

- Weight: 275

- Dimension (length x width x height): 1400*860*1260 mm

The artificial cream obtained with sunflower oil has excellent taste and high unsaturated fatty acid content. In the food industry, sunflower oil is also used to make fried fast food, such as potato chips and corn chips. The sunflower oil cake which obtained after squeezing contains 30%~36% of protein and 8%~11% of fat.

vol.2 - Sunflower / Crude and Refined Oils 18 1- SUNFLOWER CULTIVATION Sunflower (Helianthus annuus L.) is a composite annual plant. It probably originated in the south-west United Sates-Mexico area. It was introduced into Europe in the 16th century and became established as an oil-seed crop in Eastern Europe. The discovery of cytoplasmic male

What is the difference between crude and refined sunflower oil?

- Usage: sunflower oil

- Production capacity: 50-500 kg/h

- Voltage: According to your local voltage

- Warranty: 1 year, One year

- Weight: 140 kg

- Dimension (L*W*H)): 900*530* 760 mm

1-5TPD mini sunflower oil refinery plant 3D model picture. In sunflower oil refinery plant, crude sunflower oil is settled, filtrated then through degumming, deacidification, decolorization, deodorization and dewaxing five stages to absorbing substance to clarify the product. All these stages are for obtaining higher quality of sunflower oil

Refined Sunflower Oil or Refined Bleached Deodorized (RBD) Sunflower Oil, a culinary and wellness marvel, transcends its role as a mere cooking ingredient. This exploration delves into the intricate facets of this golden elixir, from its meticulous composition and refining processes to its far – reaching health benefits, historical roots,

abidjan 25t-30t per day sunflower oil press machine

- Type: cooking oil refining machine

- Voltage: 220V/380V

- Power (W): 5.5kw,7.5kw,15kw,18.5kw

- Certification: ISO9001-2008

- Weight: 1200kg, 1500kg

- Dimension (L*W*H) : 2050*1350*2000

Cold Press Sunflower Oil Machine: Extracts oil at low temperatures to retain the natural nutrients, flavor, and aroma of the oil. Used mainly for producing organic or health-focused oil. 2. Hot Press Sunflower Oil Machine: Involves heating the seeds before pressing to increase the oil yield. big capacity 25-30t/d palm kernel soybean cotton

The quality of oil strictly depends on sunflower seeds, conditions and terms of warehousing. We can give such characteristics of seeds: greasiness; moisture. These metrics connected with the breed of plant and weather conditions. There are two ways of getting sunflower oil: pressing and extraction. The process of pressing has two types: cold

Sunflower Oil Refinery Plant

- Raw Material: sunflower

- Production capacity: 350-7000kg/h hydraulic cooking oil presser

- Power (W): 7.5KW

- Voltage: match with local voltage

- Dimension (L*W*H): 900*850*1550mm

- Weight: According to the capacity of hydraulic oil presser for cooking

Our Batch Type Sunflower Oil Refinery Plant will give High-Quality Refined Sunflower Oil as Output. Functions of Sunflower Oil Refining Equipments – Neutralization Reactor: For acid refining, alkali refining and water washing. Decolorization Reactor: To Bleach the Oil and remove pigment from oil.

In today’s world, the demand for vegetable oil processing plants is growing rapidly due to the rising need for edible oils like sunflower oil.A vegetable oil processing plant plays a crucial role in transforming raw vegetable oils into refined products that are safe for consumption and have a longer shelf life.