peanut oil solvent extraction in ethiopia

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 1TPD-1000TPD

- Power (W): According to capacity

- Certification: ISO CE

- Weight: 1050 KG

- Dimension (L*W* H): 1610x615x1260mm

- Country: ethiopia

The present review was focused on four main aspects: a) extraction methods and technologies for obtaining peanut skin phenolics with an emphasis on green-solvent extraction. The oil extraction using cold-pressing method is performed at temperatures below 60 °C while in a hot-pressing condition, high temperatures are applied (Tan et al., 2020).

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Type: peanut oil processing machine

- Capacity: 350-400kg/h

- Dimension (L*W*H): 2600*1800*1800mm

- Key selling points: Enerary saving

- Warranty: 1 year

- Weight: 1700 KG

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Chemical methods are also frequently cited in the literature. They include organic solvent extraction, such as hexane , trichloroethylene , or utilizing supercritical CO 2 (SC-CO 2) adjusted through the addition of a co-solvent containing ethanol , as well as aqueous extraction processing (AEP) employing water .

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Usage: peanut oil

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Warranty: 1 year, 12 months

- Weight: 680 KG

- Dimension (L*W*H): 2400*560*760mm

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

Groundnut oil pre-pressing machine can extract most of groundnut oil, the groundnut oil solvent extraction plant can recover almost all the oils and leaves behind only 0.7% to 1% residual oil in the raw material. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

oil solvent extraction manufacturers in ethiopia

- Type: cooking oil extraction machine

- Production capacity: 2.2kw

- Dimension (L*W*H): 1200*1000*1100mm

- Voltage: 220v/380v/customized

- Weight: 268 KG

- Main components: Others

The composition, extraction, analysis, bioactivities In contrast, ultrasound-assisted extraction is more suitable for large-scale production and has better development and application potential, it could significantly increase the yield of flaxseed oil by 11.5%, and the extraction rate of PUFAs by 68.12% (Ranveer, Gutte, & Sahoo, 2015; Long et

The dry meal will be packaged for sale as animal feed. Usually, by using the peanut oil extraction method, the residual oil in the cake will be less than 1%. But different with peanut oil pressing method is that peanut oil obtained by solvent extraction method must be refined before it can be eaten.

Extraction of Edible Oil From Groundnut By using Solvents

- Raw Material: peanut

- Production capacity: 20-2000T/day

- Power (W): according to capacity

- Voltage:380 V

- Dimension (L*W*H)): various with capacity

- Weight: changes with capacity

extraction of oil from groundnuts. In the present study celluclast 1.5L was used for the pre-treatment. The effect of enzyme concentration (5-10%), temperature (50-60⁰C), pH (5.0-6.0), reaction time (1-7 h) on free oil liberated was studied. Residual oil was collected by subjecting the treated meal to soxhlet extraction for 4 h.

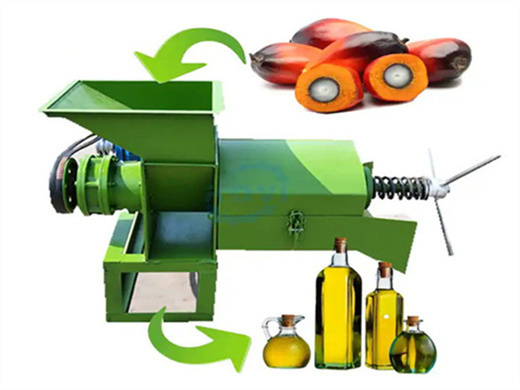

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.