TRC Advanced Technologies

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 5TPD-100TPD

- Voltage: 110V/220V

- Warranty: 1 year, 12 months

- Weight: 12 kg

- Dimension (L*W*H): 49*40*26cm

- Country: johannesburg

Pertamina johannesburg EP acquired Block 405a from ConocoPhillips johannesburg Limited in 2013, the field contains three main oil fields: Menzel Lejmat Nord (MLN), Ourhoud, and EMK. Pertamina johannesburg EP has a 65% participating interest and operatorship in the MLN Field while the other 35% remaining participating interest held by Repsol.

Peanuts: Processing Technology and Product Development

- Type: peanut oil processing machine

- Production capacity: 150-400 kg/h

- Voltage: 220 V/380 V

- Weight: 1300kg

- Dimension (L*W*H): 2200 *1600*2150mm

- Power (W): 15 KW

It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment.

,Peanut oil cold pressing technology takes high quality fresh peanut as the raw material through drying (moisture content of 4% - 5%), red skin removing (removal rate of more than 98%), crushing and conditioning before low temperature cold pressing (residual oil is below 7% after twice pressing, the cake outlet temperature is not more than 80°C).

Advanced nut processing with the peanut oil press machine

- Usage: peanut oil

- Voltage: 380V

- Press Materials: Grains and Oilseeds

- Payment terms: T/T 40% in advance, balance paid

- Application area: cooking oil, oilseeds, etc.

- Customized: Customized

The peanut oil press machine, thus, encapsulates the essence of advanced nut processing, driving a new era of efficiency and quality in the content of peanut oil production. The shift from crude oil processing to the use of this advanced technology significantly improves the yield and quality of the output.

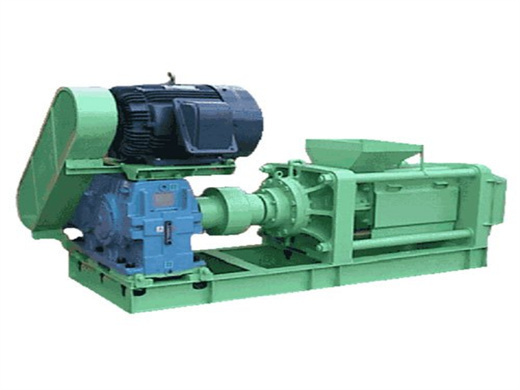

Oilseed Roll Crusher is pre-treatment processes supporting equipment for large particles of soybean, peanut and other materials-oil process. Crushing mill is one of our main products, through 20 years research, development and assimilation of advanced technology of similar products in the industry.

Groundnut Oil Mill Plant - Oil Expeller

- Type: cooking oil extraction machine

- Production capacity: 10T-5000TPD

- Power (W): 10kw-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Weight: 2T-20T

The Groundnut / Peanut Oil Production Line offered by GOYUM is robust, versatile, reliable and efficient. This Groundnut / Peanut Oil Production Plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical.

We offer you complete peanut oil production solutions. No matter small peanut oil plants from 1 TPD to 50 TPD, or large-scale peanut oil plants up to 5,000 TPD, we will work with you to make the best solution. Our peanut oil production line is a comprehensive, multi-stage setup designed to extract and refine oil from peanuts.

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Raw Material: peanut

- Production capacity: 100kg/hour-10000kg/hour

- Dimension (L*W*H): 1000X538X1050mm

- Voltage: 380V

- Weight: 140KG

- Warranty: 1 year, 1 year

The cost of raw materials is a key factor that influences production costs, and the fluctuation in raw material prices directly impacts the price of edible oils. 2. Seasonal factors: The production of some edible oils is seasonal, such as olive oil and peanut oil. Seasonal factors affect the supply-demand balance and thus influence the price. 3.

On the basis of summing up production practice experience, we optimized the internal structure of the Commerical screw alga oil press. Comparing with ordinary oil press machines, the pressure inside the chamber of the oil press produced by us is higher and the distance of embryo in the chamber is longer, so the oil extraction efficiency of our oil press is improved and the residual oil rate of