Comparative Study of Coconut Oil Extraction Method - OilCocos

- Type: coconut oil extraction equipment

- Usage/Application: coconut, copra

- Production capacity: 50-800kg/hour

- Voltage: 220V/110V

- Main components: motor, gear

- Weight: 12 KG

- Dimension (L*W*H): 450 * 180 * 300 mm

- Country: afghanistan

Discover the diverse techniques behind Coconut Oil Extraction Methods, from traditional approaches to modern innovations like cold pressing, hot extraction, and centrifugation. Unveil the quality and yield disparities between cold pressing and hot extraction, as well as the purity and efficiency advantages of centrifugation. Stay informed about the evolving methods that drive the multi-billion

The Easiest Way to Make Coconut Oil at Home: A Step-by-Step

- Type: coconut oil processing machine

- Product extraction system: roasting system

- residual oil content: maximum 1%

- Capacoty: according to your requirements

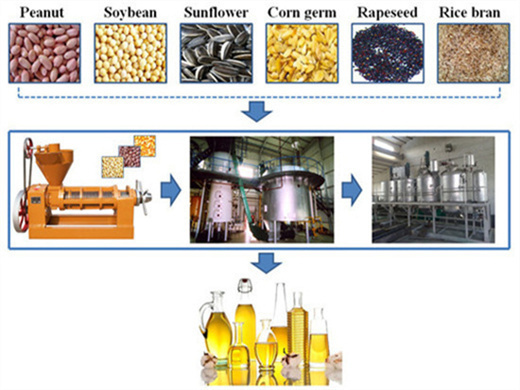

- solvent raw material: rice bran, canola, sunflower seed, peanut, soybean, groundnut, etc.

- Packaging detail: 20ft, 40ft container

Saucepan: To heat the coconut cream and extract the oil. Glass Jars: For storing the finished coconut oil. Step-by-Step Guide to Making Coconut Oil Step 1: Gather Fresh Coconuts. The first step in making coconut oil is to gather fresh coconuts. Look for mature, brown coconuts, which have a hard shell and are usually covered in hair.

Ensuring the purity, aroma and health benefits of virgin coconut oil during the extraction process is critical for any manufacturer. With Kumar’s stainless steel 304 screw/expeller-press to process virgin coconut oil you are guaranteed an oil that is as nature intended.

How Coconut Oil Is Made: The Surprising Truth & Process

- Usage: coconut oil

- Voltage: 380V/50HZ

- Power(W): according to capacity

- Color: according to the requirements for oil solvent extraction machine

- Certification: ISO9001

- Dimension( L*W*H): 1200* 400*900mm3

The careful extraction of coconut milk is a testament to the artisanal nature of coconut oil production, where every step is carried out with attention to detail and a commitment to excellence. Drying the coconut meat. Following the grating or shredding, the coconut meat is prepared for drying, a pivotal step in the dry process of oil extraction.

The amount of oil that can be extracted from 1 kg coconut varies depending on the extraction method, the maturity of the coconut, and the variety of coconut used. By understanding the anatomy of a coconut, the extraction methods, and the factors that influence oil yield, you can maximize the benefits of this versatile fruit.

How to Make Coconut Oil: A Step-by-Step Guide

- Type: cooking oil extraction machine

- Voltage: 220V/380V

- Dimension (L*W*H): Standard

- Power (W): Standard

- Weight : Standard

- Certification: CE ISO

The coconut tree, also known as the “tree of life,” produces a fruit that has many uses, including the production of coconut oil. Making coconut oil involves extracting oil from the coconut meat or copra, which can be done through various methods. Here are some of the most common ways to make coconut oil: 1. Traditional fermentation method

This paper investigates the previously overlooked potential of spent coconut meal, a byproduct resulting from the extraction of virgin coconut oil with a residual oil content of 25–54%.

Extraction Methods of Virgin Coconut Oil – Gemtech Projects

- Raw Material: coconut

- Production capacity: 100TPD

- Weight: 4000 KG

- Dimension (L*W*H): 11.48*4.26*11.81 ft

- Warranty: One year warranty against manufacturing defect.

- Main components warranty: Others

To make the most use of this natural product, the proper procedure of extraction plays a vital role. Therefore, you need to buy the best quality Virgin Coconut Oil Machinery in India for seamless and efficient extraction. Different Methods of Coconut Oil Extractions. There are various methods of extracting oil from coconut.

means [4]. Various methods have been employed to extract the coconut oil, but whichever method have been used it is still the best to avoid oil that has been rened, bleached or deodourized. This is because when the coconut oil undergo these processes, the health benet, taste and the aroma will be reduced [3, 5]. As VCO contains large amount of high