Screw Peanut Groundnut Oil Extraction Machine for Factory Use

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: as per cooking oil extractor machine specification

- Voltage: 220V/380V

- Weight: according to the specifications of the cooking oil extraction machine

- Dimension (L*W*H): according to the specifications of the cooking oil extraction machine

- Power (W): according to the specifications of the cooking oil extraction machine

- Country: uganda

This screw peanut oil extraction machine is an efficient and energy-saving oil processing equipment, which is widely used in the pressing of various oil crops such as peanuts, soybeans, sunflower seeds, etc. The equipment adopts advanced screw extrusion technology to extract oil from oil by physical pressing, which not only improves the oil

Screw Oil Press Machine Oilseed Extraction Equipment

- Type: peanut oil processing machine

- Voltage: 220 V/380 V

- Power (W): 7.5 kW

- Certification: ISO CE

- Weight: 950 kg

- Dimension (L*W* H): 1950*1300*1900mm

Screw press oil extraction’s parameter Screw oilseed extraction machine advantages. High oil output rate, compared with the old equipment, the normal oil output rate can be 2 to 3 percentage points higher, and every 100 catties of peanuts processed can increase by 2-6 catties on average.

In addition, we also have our factory for customers to visit. 2. Inspect the service of peanut oil extraction machine manufacturers For the operation of a peanut oil extraction machine, after-sales must be guaranteed. Good peanut oil extraction machine manufacturers will be very concerned about the use experience or work efficiency of their

Groundnut Oil Mill / Extraction Plant Manufacturer & Exporter

- Usage: peanut oil

- Production capacity: 1T/24 hours

- Voltage: 380V/50HZ

- Main components: engine

- Weight: 260 KG

- Dimension (length x width x height): 940*570*1170mm

Our groundnut oil extraction machines are successfully running in India, south africaia, Tanzania, Chad, malawi, Cameroon, Ethiopia, south africa, Ghana, Sudan, indonesia, lusaka & many other countries. We undertake turnkey project solutions for the complete groundnut / peanut / earthnut Oil Mill Plant.

Refined peanut oil is produced after bleaching and deodorization in cooking oil refinery plant, used as an attractive frying oil. During the refining process, the components that might cause peanut-based allergies are also removed, non-allergic. (Related Post: Peanut Oil Cold Filteration Machine) Complete Set of Peanut Oil Refinery Machine (1

Peanut Oil Extractor|Groundnut Oil Extraction Machine

- Type: cooking oil extraction machine

- Production capacity: 1TPD-1000TPD

- Power (W) : 15KW

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 700kg

This oil pressing machine adopts forced blanking device, feeding uniformly, and pressing oil fast. It can extensively crush peanut, soybean, rapeseed, sesame, sunflower seed oil, camellia seed, cotton seed, prickly ash seed, walnut kernel, Tung seed, castor oil, almond and other oil crops. Working Principle of Peanut Oil Extractor: When the new

Examine the variety of peanut kernels. There are several types of peanuts, including ordinary peanuts, pearl peanuts, multi-grain peanuts, and dragon peanuts. The ordinary type is the most suitable for oil extraction, boasting an oil content of 52-54%. seed oil extraction machines oil mill machinery How to start groundnut oil extraction business?

Choose the right peanut oil extraction machine - A buyer's guide

- Raw Material: peanut

- Certification: ISO, BV,CE, CE, ISO9001, BV, etc...

- Power: As required

- Product Type : Palm Expeller Malaysia

- Keyword: Palm Oil Productions

- Residual oil in flour : ⪙ 1%

For peanut oil extraction, we recommend a combination of mechanical extraction and solvent extraction to achieve a high oil yield without compromising on oil quality. There are many different peanut oil extraction machines that you can use for these processes, depending on your desired product qualities and the scale of your operation.

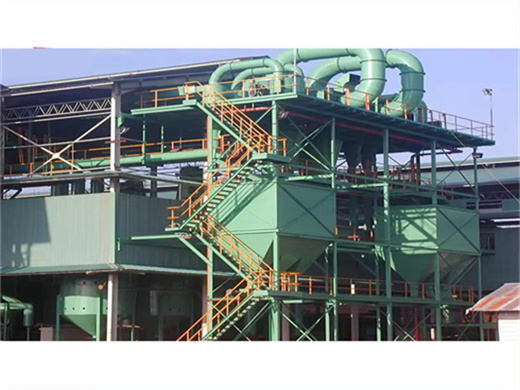

For large scale peanut oil production line, the processing capacity is usually more than 50TPD. In order to improve the oil yield and further improve economic efficiency, We will divide the whole processing process into peanut oil pre-treatment production line and peanut oil solvent extraction production line. The pre-treatment plant mainly performs preliminary cleaning and pressing of peanuts. The oil cake obtained in this workshop will be transported to the solvent extraction workshop, where the chemical reagent n-hexane is used to leach the oil cake and get more gross oil. At the end of the whole process, the residual oil rate can be less than 1%.