Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 10-1000MT

- Voltage: 380V

- Certification: CE and ISO

- Dimension (L*W*H): 1200* 400*900mm3

- Power (W ): According to capacity

- Country: nigeria

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

- Type: sunflower oil processing machine

- Production capacity: 20-2000T/day

- Voltage:as capacity of oil extraction plant oil extraction

- Weight:As capacity of oil extraction plant

- Dimension (L*W*H): as capacity of oil extraction plant

- Power (W): as capacity of oil extraction plant

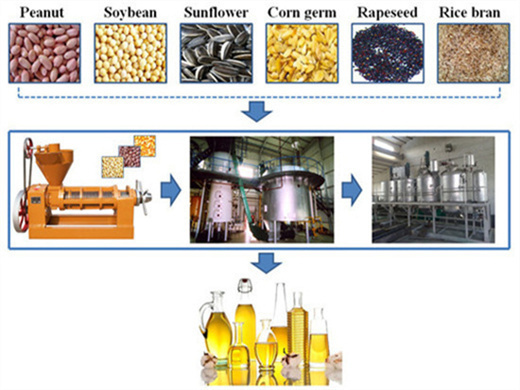

Steps Involved in Sunflower Oil Extraction Process. The sunflower oil extraction process involves several steps, including cleaning, dehulling, cooking, pressing, and refining. Cleaning involves removing any foreign material and impurities from the seeds. The dehulling process helps to remove the outer shell of the seed to access the oil-rich

Compared with the sunflower oil pressing method, the sunflower oil solvent extraction method has a higher oil yield but also higher cost. In addition, the sunflower oil solvent extraction method requires the use of chemical solvents, which have some impact on the environment, so environmental protection issues need to be considered.

How is Sunflower Oil Processed?

- Usage: sunflower oil

- Production capacity: 1-100t/d

- Place of Voltage: 220V/380V

- Weight: different

- Dimension (L*W*H): 1055*805*345mm

- Power (W): different

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

The conventional procedure for sunflower oil extraction involves seed preparation, mechanical extraction (in which a press cake or oilcake containing 16–24% of oil is obtained after continuous pressing), and a final stage which is the solvent extraction from ground oilcakes or expanded material, known as “collets” (porous cylinders

Step-by-Step Guide on How Sunflower Oil is Made - Earthy Tales

- Type: cooking oil extraction machine

- Voltage: 380V, 380V

- Appearance: Horizontal, Vertical

- Condition: new, new

- Press series: fifth, fifth

- Press materials: sunflower, soybeans, coconut, peanuts, mustard

Sunflower oil extraction, as the name suggests, is the process of obtaining oil from sunflower seeds. It's a meticulous process that involves several steps to ensure the purity and quality of the final product. Harvesting Sunflower Seeds. The journey of the sunflower oil manufacturing process oil begins in the vast fields where sunflowers sway

Sunflower oil ensures hydration and the maintenance of skin suppleness. Sunflower oil is an effective emollient that moisturizes the skin through its fatty acids. Indeed, naturally present in sebum, they strengthen the hydrolipidic film on the surface of the epidermis, which limits water loss and ensures the maintenance of the skin barrier.

Sunflower Oil Press & Oil Extraction Process - Site

- Raw Material: sunflower

- After-sales Service: After-sales Service Support

- Voltage: 380V

- Warranty: 12 Months

- Power: 3kw

- Customized: Customized

The U.S. is recognized as having the highest quality of sunflower products due to technology that currently surpasses any other supplier. Sunflower oil can be extracted during the solvent extraction process using chemical solvents or by a sunflower oil press (screw press) used to squeeze the oil directly from sunflower seeds by crushing them

Oilseed processing involves extracting oil from seeds, such as sunflower, canola, and soybean. These oils are widely used in cooking and other applications. Due to its lower protein content, the crushed seed residue left behind after oil extraction has traditionally been limited to lower-value applications, such as feed for ruminants and dairy