Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 1t/day-1t/hour-100%

- Voltage: 220V/380V

- Main components: motor, bearing

- Weight: 330 KG

- Dimension (L*W*H): 1050* 800*1400mm

- Country: zambia

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

Sunflower Oil Press & Oil Extraction Process - Site

- Type: sunflower oil processing machine

- Production capacity: 1-100TPD

- Voltage: 380v or according to local voltage

- Weight: 1050 KG of sunflower oil machine sunflower

- Dimension (L*W*H) : 430*230*350 of sunflower oil machine

- Power: 2.2KW

Sunflower oil can be extracted during the solvent extraction process using chemical solvents or by a sunflower oil press (screw press) used to squeeze the oil directly from sunflower seeds by crushing them. This method of cold-pressing sunflower seed oil under low-temperature conditions is a preferred method for those seeking an extraction

Sunflower seed processing focuses on sunflower oil as the most valuable product. It is used as high-value oil in various food applications. The deoiled meal is considered a byproduct and is mostly used as animal feed. In 2011, annual world production of deoiled sunflower meal was at 16 million tons (FAO, 2013). The deoiled meal composition

First stage of bio-jet fuel production: non-food sunflower

- Usage: sunflower oil

- Voltage: 220V/380V

- Power (W): 4kw

- Model: GL-S001

- Weight: 300KG

- Dimension (L*W*H): 2400*900*1220 mm

There were no rancid smell or spoiling SS, SM, and FSM found during the oil extraction trials. These feedstocks had good quality prior the tests. Table 1 lists the particle size, bulk density, and moisture content of the sunflower seeds and meats. The length and width of seed or meat samples were measured based on the ASTM D 4791 standard.

Oil extraction from sunflower seeds resulted in the production of 19 million metric tons of sunflower cake in 2017 [8]. Currently, the most commonly used method of processing in the industry of

Sunflower oil obtained by a new device and extraction system

- Type: cooking oil extraction machine

- Appearance: Vertical

- Custom: Customized

- Press materials: sunflower, soybean, coconut, peanut, mustard

- Transportation package: in wooden packaging, according to customer specifications: various

- Production capacity: 98%- 100%, 100 pieces per month

The yield, calculated as the ratio of the mass of the obtained oil to the mass of the grain or seed used, and various properties of the oil obtained through hydrostatic pressing were determined. The results show that the yield of vegetable oil increases with both higher pressure and longer extraction times.

The aim of this work was the extraction of oil from the seeds of two types of Sunflower (Helianthus annuus) plants, (Bazian and Shahrazour).Two solvent extractions (N-hexane and Methanol) and two degrees for moisture (4 and 5%) were used for oil extraction.The results showed that the use of N-hexane was the most acceptable in

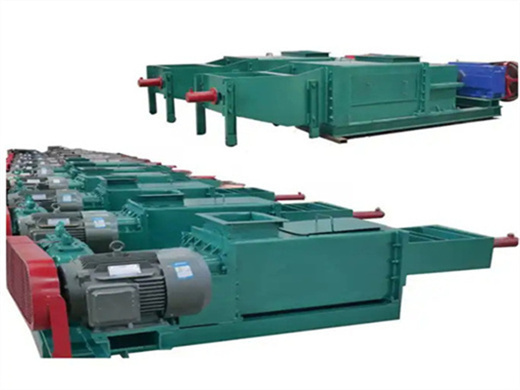

Worldwide Sunflower Seed Processing - Shelling Machine

- Raw Material: sunflower

- Production capacity: high

- Dimension (L*W*H): customization

- Voltage: 220V/380V

- Weight : 1100 KG

- Main components: Pressure vessel, Bearing

As the edible oil, sunflower seed oil primary uses are as salad or cooking oil or in margarine. Sunflower seed oil is cold-pressed. The cold-press entails minimal processing to produce a light, flavorful oil suitable for some cooking needs. Sunflower seed oil manufacture involves seeds cleaning, seed de-hulling, seeds

Considering the American Society for Testing and Materials (ASTM 4172-B) standard, all the experiments are conducted for different loads from 45 kg to 70 kg, the balk temperature was increased