How Much Can Invest a Fully Automatic Peanut Oil Production

- Type: peanut oil refinery plant

- Usage/Application: peanut, groundnut

- Production capacity: 50~100T/D

- Voltage: 380V

- Residual oil yield: <7%

- Dimension (L*W*H): 1000 *538*1050Weight: 1050 KG

- Power (W) : 5.5 KW

- Country: johannesburg

The general capacity we can provide for peanut oil processing plant ranges from 5 to 400 tons per day. Taking the smallest peanut oil production line (5TPD) as example, the totally investment for a complete automatic peanut oil production line is $ 8,500 around (Not include the oil refining equipment). Please note all the equipment included

lesotho peanut oil press machine 2000 tpd edible oil

- Type: peanut oil refinery machine

- Production capacity: ≥98%

- Voltage: 380 V/50 Hz

- Oil type: flax seed oil, flax seed oil rap, tea seed oil, basil oil, SESAME OIL, pine nut oil, walnut sunflower seed oil, OLIVESafflower seed oil, oil

- Main components: Others, gear, gearbox, frame, squeezing part, feeding system

- Dimension (length x width x height): 1710 x 460 x 1380 mm Weight : 600 KG

A Small edible oil production line is designed for small to medium-scale edible oil mill plants, with capacities ranging from 1 TPD to 50 TPD, providing an efficient, cost-effective solution for producing high-quality edible oils from various oilseeds like sunflower, peanut, peanut, canola, rapeseed, Peanut, and more.

Edible Oil Press Machine, 100tpd~10, 000tpd Soybean Canola Sunflower Cotton Palm Rice Bran Corn Peanut Oil Extraction Refinery Machine, China Factory OEM US$ 500000-8000000 / Set (FOB Price) Get Price

Small Oil Pressing Line. Small Oil Mill Plant. Edible Oil

- Usage: peanut oil

- After-sales service: online support, video technical support

- Voltage: 380V

- Outgoing inspection video: provided

- Applicable industries: food and processing Beverage factory

- Advantage : high productivity, easy operation

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

Peanut Oil Processing. Peanut oil is an edible oil extracted from peanuts (also known as groundnuts or ground beans). Peanut oil is usually extracted by two methods: pressing and extraction (Read more: solvent extraction of groundnut oil >>). Among them, the main process steps include cleaning, shelling, drying, pressing, and refining.

Peanut Oil Production Line,Peanut Oil Pressing Plant - Oil mill

- Type: cooking oil refining machine

- Production capacity: 150-300 kg/h

- Dimension (L*W*H): 1900* 1200* 1600 mm

- Voltage: 220 V/380 V

- Weight: 1200 kg

- Main components: motor

Small-scale peanut oil plant (1-10 TPD): Simple mechanical pressing machines and basic refining units. Medium-scale peanut oil plant (10-50 TPD): More advanced pressing equipment, potentially combined with solvent extraction and semi-automated refining systems.

Edible oil refining process systems. Our edible oil production line portfolio. After oil clarification (for pressed oils), the oil can be refined as shown below. The crude oil is then transferred either to special degumming in the physical refining route, to water degumming, or directly to neutralization in the chemical refining route.

Fully Automatic Groundnut/Peanut Oil Production Line

- Raw Material: peanut

- Production capacity: 1-100T/DAY

- Dimension (L*W*H): 200*20*8m

- Voltage: 380v

- Weight: 50 KG

- Main components warranty: 3 years

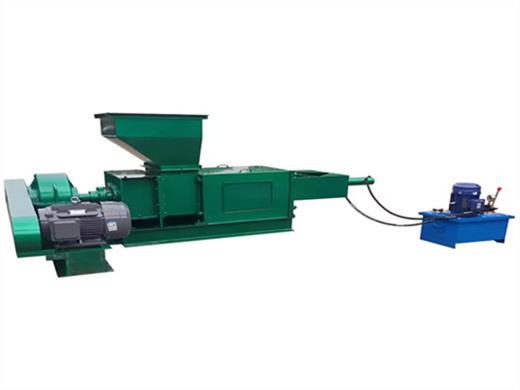

What parts are included in a peanut oil screw press? Peanut oil screw press mainly consists of five parts: hopper, gear box, press chamber, press screw and frame. Among them, the press screw is the key of the whole peanut oil screw press, and the choice of its material will affect the quality and service life of the press. 2024-08-26

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.