Soybean Oil Production line – Liangli Machinery Equipment Company

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 10 kg per oven

- Voltage: 220

- Key Selling Points: Energy Saving

- Weight: 70KG

- Dimension (length x width x height): 50*60*110 cm

- Country: botswana

According to the quality of oil and the different requirements of customers, we can reasonably select and combine the refining process, select the best process route, and exquisite equipment production and automatic control system to provide customers with perfect technical services and meet domestic requirements.

Soybean Oil Production Line

- Type: soybean oil processing machine

- Production capacity: 60-700kg/h

- Voltage: 220V

- Main components: Motor

- Weight : 500 KG

- Dimension (L*W*H): 1250x900x1300mm

With Dingsheng Machine, we provide automatic, continuous and mechanized production conditions, which increased capacity while also reducing the level of product waste the production of soybean. The process design of the whole soybean oil processing project is reasonable, compact and elegant, to achieve lower overall operational costs and higher

The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process. Our advanced soybean oil equipment, such as solvent extractors and automatic control systems, ensures high yields and consistent quality of both crude and refined oil.

Fully Automatic & Economic Soybean Oil Production Line

- Usage: soybean oil

- Production capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Weight: 950KG

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Power (W): 5.5 ~ 18.5 KW

Over the years, Newamstar has made continuous breakthroughs and innovations in the field of edible oil filling and packaging technology. On the one hand, it has successively launched packaging solutions for the production line of high-speed blowing-filling-capping combibloc for 5L large bottles and 500ml small bottles.

Our soybean oil production line is designed to meet the international market's demand for efficient and sustainable production of soybean oil. This complex production line uses the most advanced technology to ensure that each step from soybean cleaning, crushing and extrusion to extraction and refining achieves optimal performance while

Soybean Oil Production Line - Hongde Group

- Type: cooking oil extraction machine

- Production capacity: 50-60 kg/h

- Dimension (L*W*H): 1450*870*1190 mm <br /Weight: 320 KG

- Voltage: 220V/380V

- Main components: Motor

- Oil type: Cooking oil

Soybean oil processing plant Soybean → Cleaning → Crushing → Softening → Flaking → Cooking → Pressing → Filtering Soybean oil solvent extraction plant soybean should be pretreated in soybean oil processing plant. It can produce high capacity soybean oil. Soybean Oil Refinery

Edible Oil Production Line Introduction. We are specialized in customizing different capacity edible oil production lines. family-style workshops , small oil factory or large-scale which the capacity is 5T-50T.The oil production line includes oil seeds pretreatment, oil seeds pressing, crude oil refining and refined oil packing .We are also design different oil press line with different oil

QI'E Grain and Oil Machinery Co., Ltd. - Leading Manufacturer

- Raw Material: soybean

- Production capacity: 80kg/h~600kg/h

- Power (W): 5.5 ~ 7.5 KW

- Voltage: 380V

- Dimension (L*W*H): depending on the model of cooking breast pump

- Weight : depending on the model of the cooking breast pump

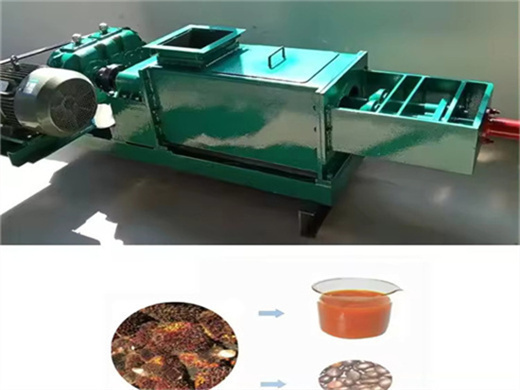

Ours hot sale oil machine include : palm kernel oil production line equipment, Soybean oil production line,palm oil production line equipment,Vegetable Oil Solvent Extractor,Cold Press Oil Machine,Sunflower oil extractor,Edible oil refinery machine,Mini oil mill plant,Multifunction oil press machine,Automatic oil press machine etc. QI ' E Group

Brief Overview of Soybean Oil Production Line. 1. Advanced soybean oil extraction process, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automatic control. 3.