Sunflower Oil Making Machines for Sale

- Type: sunflower oil plant

- Usage/Application: sunflower

- Voltage: 380/440

- Appearance: Vertical

- Personalized: Personalized

- Press Series: Second

- Press materials: sunflower, Rice, Sunflower, Mostar

- Country: botswana

10 ton/d sunflower oil processing plant in Moldova; 150 ton/d sunflower oil manufacturing plant in Russia; Sunflower Oil Making Process. Sunflower oil manufacturing is a complex process involving various stages. The quality of the oil depends on the oilseed quality as well as the quality of sunflower oil processing machine. Sunflower seeds need

High-Quality Sunflower Oil Press Machine | Efficient & Cost

- Type: sunflower oil processing machine

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V

- Weight: 30 tons

- Dimension (L*W*H): 1.5*2.6*3.6M

- Power (W): 15KW

The small sunflower oil processing plant is a complete set of equipment designed for small-scale sunflower oil production, providing efficient and environmentally friendly solutions for the local market, suitable for small and medium-sized agricultural enterprises and processing plants.

Sunflower Seed Oil Press Machine for Edible Sunflower Oil Making. Sunflower seeds, the fruit of sunflower, contain 30% to 45% fat, up to 60%. Sunflower seed oil, extracted from sunflower seeds, is golden yellow, clear and transparent, has features smell fragrant. As an important cooking oil, sunflower seed oil contains a lot of linoleic acid

Efficient Sunflower Oil Production Machines

- Usage: sunflower oil

- Production capacity: 1-500T/D

- Voltage:380V

- Weight: changed with capacity

- Dimension (L*W*H): various with capacity

- Power ( W): according to capacity

- Mechanically presses the sunflower seeds to extract the oil. - Can be either a cold press (preserves nutrients but has a lower yield) or hot press (higher yield but may lose some nutritional value). 4. Oil Filtration Machine: - Filters the oil to remove solid particles, impurities, and seed residue. - Produces clear, high-quality sunflower

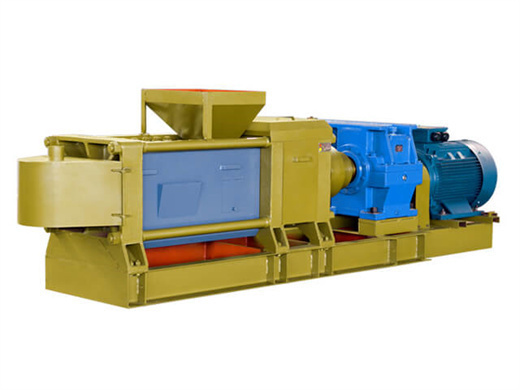

Capacity 1 TPD to 5,000 TPD. The sunflower oil production line includes cleaning, shelling, kernel separation, cooking, pressing, filtering, extracting, refining, and packing. Some steps can be customized based on specific requirements, fully automated or semi-automatic options for varying budget levels.

High-efficient Automatic Sunflower Oil Machine for sale

- Type: cooking oil extraction machine

- Production capacity: 5TPD

- Dimension (L*W*H): according to cooking capacity

- Voltage: 220/380V

- Weight: 1100 KG

- Warranty: 2 years

6YL series automatic sunflower oil machine is a highly efficient and versatile tool for extracting oil from various seeds such as rapeseed, peanut, soybean, sesame seed, and hippophae rhamnoides. Equipped with electronic temperature control, automatic heating, and vacuum oil filter, this machine ensures a high oil rate and multi-purpose

Type 2: automatic sunflower oil press machine. An automatic sunflower oil press machine is also called an automatic temperature control sunflower oil press machine. Compared to screw sunflower oil press machines, this type of sunflower oil press machine uses electric heating coils for heating and controls the temperature automatically.

Sunflower Oil Production Plant - Oil press machine, Hydraulic

- Raw Material: sunflower

- Weight (KG): 360

- Fields of Capacity machinery: According to model

- Main components: PLC, Motor

- Function of the machinery: cooking and mixing

- Product Material: 304 stainless steel

The sunflower oil squeezed by the automatic sunflower oil press contains a certain amount of oil residue. In order to improve its purity, the sunflower oil machine is equipped with two vacuum oil filter barrels. The filtered oil has less oil foam, and it is clear and translucent, and the oil fragrance is overflowing. Step 4, Refining

Sunflower Oil Press . The YZS-100A sunflower oil press is capable of both cold pressing and hot pressing. Its design and performance is quite suitable for those who do business in country markets or who run a small-scale oil mill. Control at each stage of production in the oil expeller press allows for clean and reliable performance.