Palm Oil Mill Plant Production Line - QI'E Group

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100% cold hydraulic oil compression motor

- Voltage: 220V/380V

- Weight: 1000KG

- Dimension (L *W*H): 900*850*1550mm

- Power (W): 1.5 kW

- Country: malawi

Batch type is the ideal choice for small-sized production (1-20TPD), while the middle-large size production line (20-50TPD), fully continuous refinery line(50-600TPD). The oil refining process is suitable for refining soybean oil, rapeseed oil, sunflower oil, palm oil ,cottonseed oil and etc. QI'E GROUP is a large - sized joint - equity

Palm Oil Production Line - Oil mill

- Type: palm oil processing machine

- Production capacity: 20 kg/h

- Voltage: 220v/110v

- Main components: Motor

- Weight: 53 KG

- Dimension (L*W*H): 620*330*710mm

The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

Physical refining process is suitable for both crude palm oil and palm kernel oil. Improve production capacity and refining rate. Reduce production cost. Shorten processing time. Directly recovering highly purified distilled fatty acids. Reduce waste water and waste gas problems. There is no waste water and waste gas produced by the cracking of

What is the difference between a batch refinery, semi

- Usage: palm oil

- Production capacity: 5.6 t/24 h

- Voltage: 380 V

- Main components: motor, pressure vessel, pump, PLC, other, gear, bearing, motor, gearbox

- Weight: 1500 KG

- Dimension (length x width x height): 2300*1500*1800 mm

During palm oil refining process, the main oil loss is from deacidification step. Batch type palm oil refining processing line use alkali and acid neutralized chemical way to remove acid. But continuous palm oil refining processing line use steam to extract fatty acid. In this way, the batch type oil loss will be higher than continuous refining

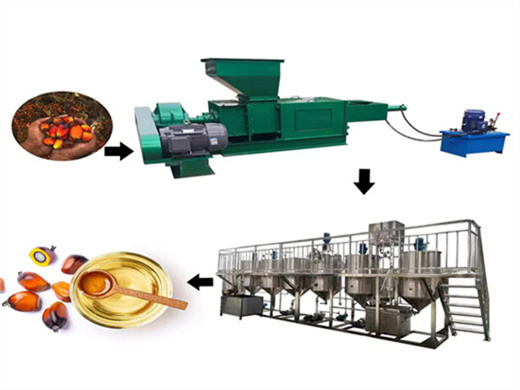

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

Palm Oil Processing Plant | Sunflower Oil Refinery | Palm Oil

- Type: cooking oil extraction machine

- Production capacity: 80kg/h

- Dimension (L*W*H): 1400*1000*1200mm

- Voltage: 220V/380v/

- Weight: 80 KG

- Main components: Motor

The palm oil extraction is to be done with the fresh palm fruit to avoid the deterioration of palm oil so the countries doing the cultivation are extracting the oil themselves. The crude palm oil comes out as yellow red or dark yellow in colour and the taste of the crude palm oil is sweat.

Batch type edible oil refining plant:This process is to refine the crude oil batch by batch, it is more suitable for small capacity like 1-2-3-5-10TPD. Refine Crude Oil: palm oil, cottonseed oil, corn germ oil, peanut oil, soybean oil, sunflower seed oil, rapeseed oil, rice bran oil, coconut oil,animal fats and oil etc.

Palm Oil Mill Plant Production Line - HUATAI OIL MACHINE

- Raw Material: palm

- Production capacity: 3.5-4 kg/h

- Dimension (L*W*H): 460*160*350 mm

- Voltage: 220 V

- Weight: 16 KG

- Main components: pressure vessel, gear, gearbox

Complete palm oil production process in a large-scale palm oil factory. Fresh fruit bunches (FFB) of oil palm after the fruit is harvested, it is processed in a palm oil mill, where the FFB is sterilized, digested, and pressed to extract palm oil. The extracted oil is then clarified and sent to a crude palm oil refinery plant, or fractionation

Palm Oil Mill process is quite different from other vegetable oil seeds processing. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours. At the Palm oil mill, the main products that are produced from FFB to Crude Palm Oil (CPO) and Palm Kernels.