30~60 TPD Complete Soybean Oil Extraction Plant Sent to mozambique

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 5 t/h

- Voltage: 220 V 380 V

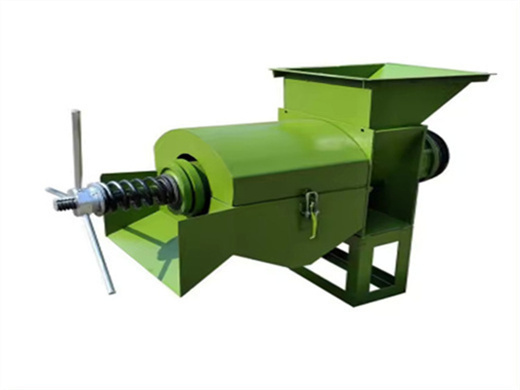

- Press method:: Screw squeezed press

- Oil item: oil press machine

- Dimension (length x width x height): 1.2 x 0.78 x 1.1m Weight: 300kg Main components: motor, pressure vessel, PLC

- Country: mozambique

Complete Soybean Oil Extraction Plant Sent to mozambique. Our Machinery is a professional soybean oil extraction machinery manufacturer and supplier in China, with a professional R&D team and project managers, providing the turnkey solution for home use single machine soybean screw oil press and Soybean oil extraction machine plant.

BEST Soybean Oil Machine for Sale|Screw Pressing & Solvent

- Type: soybean oil processing machine

- Production capacity: high effectiveness for cooking oil processing machine

- Voltage: 220V, 380 V or other

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W): depends on capacity

The complete soybean oil manufacturing process requires a series of oil processing machine based on the specific processing steps, including cleaning machine, cooking machine, oil extraction machine, oil filter machine, solvent extraction plant, oil refining plant, and more. The selection of soybean oil processing machine should be closely

If your processing capacity is relatively small, Our Machinery recommends that you configure a rolling caldron fry seed machine, screw oil press machine and plate frame filters, which can process 1-10 tons of soybean oil raw materials per day, which is suitable for the daily production needs of small oil press mill.But if your processing

How To Choose The Best Soybean Processing Machine For Your

- Usage: soybean oil

- Voltage: 380V

- Power (W): according to capacity

- Certification: CE and ISO

- Weight: various

- Dimension (L*W*H): according to capacity

Solvent extraction: A chemical method that uses solvents like hexane to extract oil from soybeans. This method is highly efficient, typically used in industrial-scale plants for large volumes of oil extraction. 2. Soybean Crushing Machines. Soybean crushing machines are used to break down soybeans into smaller pieces, also known as flakes or

In addition to the soybean pretreatment stage of soybean cleaning, crushing and softening, embryo making, before the extraction of soybean oil, the soybean embryo steaming directly affects the subsequent process and the quality of the oil, and aimed at destroying the cell structure of soybeans, help to improve the extracting rate of oil.

Soybean oil production process in a edible oil plant

- Type: cooking oil extraction machine

- Production capacity: 1TPD-1000TPD

- Power (W): fruit oil mill for cooking

- Voltage: 380V

- Dimension (L*W*H): fruit oil mill for cooking

- Weight: fruit oil mill for cooking

If yes, join us to unveil the fascinating soybean oil extraction process. Have you ever wondered how modest soybean seeds become nutritious and delectable edible oils? .gatsby-image-wrapper noscript [data-main-image]{opacity:1!important}.gatsby-image-wrapper [data-placeholder-image]{opacity:0!important}

In this regard, the soybean oil extraction machine engineer of Henan Glory Company recommends that you can choose the solvent extraction method for extracting soybean oil when your production capacity is above 30tpd. In other words, if your production capacity is small, it is not cost-effective to buy soybean oil extraction machines.

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Raw Material: soybean

- Production capacity: 40-600kg/hour

- Dimension (L*W*H): 380 * 145 * 280 mm

- Voltage: 220V/110V

- Weight: 6 KG

- Main components: motor, gear

Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

The working principle of extrusion in oil extraction process: the flakes or the powder oilseeds materials is fed into extruder machine, then in the propulsion of the spiral, by the spray of direct steam heating and tempering, the role of the spiral and shear pin in the cavity, resulting in strong friction, chopping, kneading, extrusion