palm oil line

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Processing material: all kinds of oilseeds

- Custom: customized

- Automatic grade: Automatic

- Power source: electric, steam

- Certification: ISO9001, ASME

- Country: botswana

The pulp is then pressed, which bursts the oil-containing cells, releasing the palm oil. There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil

Palm oil milling equipment and machinery - Alfa Laval

- Type: palm oil processing machine

- Production capacity: 35-50 KG/H

- Voltage: 380V, 220V, 110V, 440V

- Weight: 1000KG

- Dimension (L*W*H): 900*850*1550

- Power (W): 1.5 KW

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as

'TINYTECH PLANTS', established in the year 1983, is the pioneer in oil mill machinery, palm oil mill machinery, refinery plants not only in India but we have large customer base all over the world in 119 countries. 'TINYTECH PLANTS' began by manufacturing Mini oil mills to produce oil from any kind of oil seeds.

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Usage: palm oil

- Production capacity: High

- Dimension (L*W*H): 9.51*3.15*7.05 ft

- Oil type: Cooking oil

- Warranty: 1 year warranty against manufacturing defect.

- Weight: 0 KG

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Palm Oil Machine. Henan Hongde Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining.

Palm Oil Mill Processing Machines - Palm Oil Mill Machine

- Type: cooking oil extraction machine

- Production capacity: 25-50kg/h

- Voltage: 220V/380V

- Warranty: 1 year, 12 months

- Weight: 280 KG

- Dimension (L*W*H): 1400*860 *1260 mm

Palm oil mil process of purification: oil purification process to improve palm oil purity. Palm oil mil process of drying: continuous Vacuum drier with the oil out of the water, the water can be reduced to 0.1%. 9.Palm oil mil process of depericarper (splitter): through floating dry processing the fruit core and fibers separated. Fiber

Hello, sir. We can supply compete palm kernel oil production plant from 1tpd to 400 tpd. A 10 tons per day palm kernel oil production line will cost about is $ 60,000 around. The required equipment is palm kernel crushing and separating machine, palm kernel oil extraction machine, oil filter machine, palm kernel oil refining machine, etc

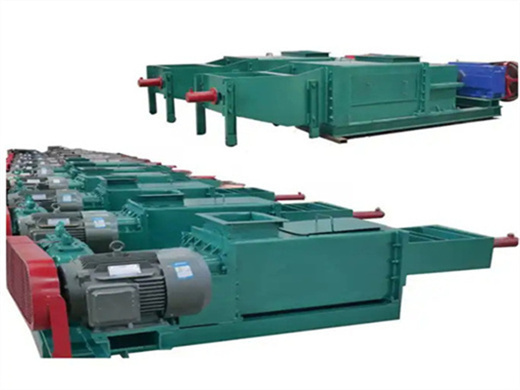

Palm Oil Processing Production Line

- Raw Material: palm

- Production capacity: 500 TPD cooking oil refining

- Power (W): depends on capacity

- Voltage: 220V/380V /440 V

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

Palm Oil Mill process is quite different from other vegetable oil seeds processing. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours. At the Palm oil mill, the main products that are produced from FFB to Crude Palm Oil (CPO) and Palm Kernels.