Small Automatic Palm Oil Press Machine in malawi

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-100T/D

- Voltage: 380V/440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W) : 20-50KW

- Country: malawi

High quality high oil yield and design of Palm Oil Production Line is the key to success of palm oil plant business. Hongde Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press, palm kernel oil extraction machine, CPO Refinery, and palm oil fractionation plant. Our team offer turnkey production solution for complete palm oil processing project with competitive cost!

Small Scale Palm Oil Mill Plant, Equipmentfor 1-20t/d Production

- Type: palm oil processing machine

- Voltage: 220V/110V 60Hz/50Hz

- Dimension (L*W*H): 41cmX16cmX31cm

- Keyword 5: oil presser machine price in India

- Keyword 4: domestic oil presser machine

- Weight: 11KG

One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory. Main Processing Equipments for Crude Palm Oil Mill Plant. The main equipment for small palm oil mill is palm fruits cooking and sterilizing tank, FFB Stripper and screw palm oil press machine

According to the degree of automation, the refinery process can also be divided into Batch Refinery Plant, Semi-continuous Refinery Plant and Continuous Refinery Plant. Batch type is the ideal choice for mini and small sized production (1-20TPD), while the latter two are normally designed for middle-large size production line (10-50TPD).

100 ton/day best quality processing palm oil machine in malawi

- Usage: palm oil

- Production capacity: 98%-100% palm oil extraction

- Voltage: 220 V / 380V/440V

- Weight: 1200kg

- Dimension (L*W*H): 1400*600*600mm

- Power (W): 7.5kw

Core Components: Motor, Pressure vessel, Pump, Gear, Bearing, Engine, Gearbox, Palm oil processing plant Warranty: 1 Year, Video technical and Online support, Field maintenance repair service Oil Product name: Cooking Oil Making Machine

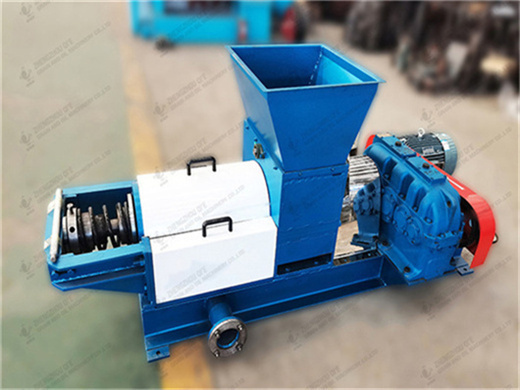

There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

Low Cost Mini Palm Oil Mill Plant for 1-10 ton Production Line

- Type: cooking oil extraction machine

- Production capacity: 80-600 KG/H

- Voltage: 110V, 280V, 380 V, 440 V

- Weight: 1050 KG

- Dimension(L*W*H): 1610x615x1260mm

- Power(W): according to capacity

For mini palm oil mill plant with 1~10 ton per day production output, the processing flow is relatively simple, including threshing, digesting and sterilizing, oil pressing and oil filtering. One of the reasons why small scale palm oil mill are very common in the global market including Indonesia and south africaia is that they are affordable and they

Some of our customers may needs mini scale or small scale palm oil production equipment to help them enter into this industry as a starter. Therefore, we also develops small scale palm oil extraction machines that has small capacity and requires less investment cost. The mini palm oil processing plant we provides is about 1~20 tons per day. If

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- Voltage: 380v

- Weight: 80KG

- Dimension (L*W*H): 1580*430*1190mm

- Main components : Motor

- Oil Product With power: 15-38kw

Main Station of Palm Oil Extraction Plant( Whether it is a small scale palm oil machine or large scale palm oil processing plant all include the following station): 1) Palm fruit reception station; 2) Palm fruit sterilizing station; 3) Palm fruit threshing station; 4) Palm fruit digesting & pressing station; 5) Crude palm oil clarification station;

8.Palm oil mil process of clarification: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge taken out separated (by 90% pure oil) is taken out