Cottonseed Oil Production Line

- Type: cottonseed oil line

- Usage/Application: cottonseed

- Production capacity: 30TPD-1000TPD

- Voltage: According to customer demand

- Weight: According to customer demand

- Dimension(L*W*H): According to project

- Power (W ): According to project

- Country: nairobi

The deodorization process can not only remove the odors from crude cottonseed oil, but also improve smoke point, flavor, steadily and quality of final oil. At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature.

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 100%

- Voltage: 380V

- Weight: 630

- Dimension (L*W*H): 1650*1200*1720

- Power (W): 2KW

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

For large cottonseed oil production lines with capacities of over 30 TPD, the solvent extraction method is usually adopted working together with cottonseed oil pre-press to maximize the oil yield. The large cottonseed oil production line includes a cottonseed pretreatment and pre-pressing workshop , a cottonseed cake solvent extraction workshop

Cottonseed Oil Extraction Plant

- Usage: cottonseed oil

- Production capacity: 22~25 tons/day

- Weight: 0 KG

- Oil type: Cooking oil

- Main components: Gearbox

- Warranty: One year warranty against manufacturing defects.

Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3. Cottonseed oil extraction plant has multiple oil extractors for selection and advanced mineral oil system. 4.

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed.

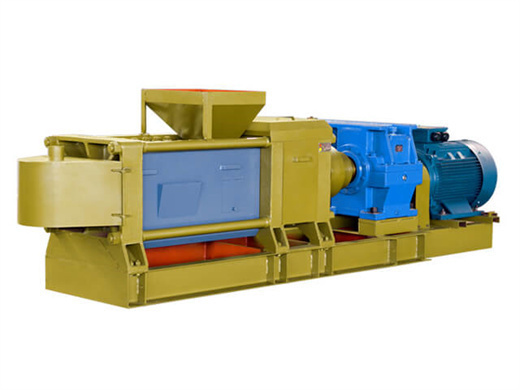

Edible Oil Processing Mill Machinery,Seed Oil Pressing

- Type: cooking oil extraction machine

- Production capacity: 45~70kg/h

- Power (W): 2.2 KW

- Voltage: 220V~380V

- Dimension (L*W*H): 1000*1300*1950mm

- Weight: 1300 kg

We are national key manufacturing enterprise of complete set of oil mill machinery,outstanding corporate member of Chinese Cereals and Oils Association,Chinese Top 10 cereals enterprise, high-tech enterprise and provincial enterprise abiding by contracts and keeping promises.

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Turn-key Oil Milling/Pressing Plant, Oil Extraction

- Raw Material: cottonseed oil

- Production capacity: 50TPD Solvent Extractor

- Power ( W): 3KW-15KW

- Voltage: 380V

- Dimension (L*W*H): 450*230*350 mm

- Weight: 700 kg

Our Machinery has its own brand of oil mill plant named as KMEC (Henan Kingman Mechanical & Electrical Complete Plant Co., Ltd), which is established in 1990, dealing principally oil pressing machinery and turn-key oil processing projects including designing, manufacturing, installing and debugging.

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal