Made In Sunfloweroil Refining Mill Equipment in kenya

- Type: sunflower oil refining equipment

- Usage/Application: sunflower

- Residual oil in flour: less than 1%

- Consumption of solvent: less than 2 kg/t

- Crude oil moisture and volatile matter: ≤ 0.30%

- Moisture of finished food: ≤ 13% (adjustable)

- Energy consumption: no more than 15 KWh /T

- Country: kenya

Sunflower oil manufacturing is a complex process involving various stages. The quality of the oil depends on the oilseed quality as well as the quality of sunflower oil processing machine. Sunflower seeds need to be pre-treated prior to oil extraction process to separate out impurities. This is followed by oil pressing and solvent extraction.

Sunflower Oil Refinery Plant

- Type: sunflower oil refinery machine

- Production capacity: 150-20000 kg/hour

- Voltage: 220v/50Hz

- Core component warranty: 6 months

- Weight: 40 KG

- Dimension (L*W*H): 50*30*78cm

The demand for oils with a lower degree of unsaturation than those of traditional oils has significantly increased the availability of oils of high thermostability. Refining the crude sunflower oil on our Tinytech refinery machine will eventually produce an additive free product having good oxidative, flavor and cold-test stabilities. Idea

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Sunflower Oil Refining Process Essentials for Optimal Effects

- Usage: sunflower oil

- Supply type: OBM (original brand manufacture)

- Available quantity: 100000 kg

- Appearance: Light Yellow Liquid

- Purity: 100% Pure Nature

- Name of the product: Sweet palm oil

Sunflower Oil Refining Equipment List; Sunflower oil hydration and degumming equipment: 1. Hydration tank (intermittent, same as alkali refining pot) 2. Vacuum dryer 3. Desolventizer (dedicated to remove residual solvents from leaching branched hairy sunflower oil) Sunflower alkaline refining and deacidification machines: 1. Alkali refining pot 2.

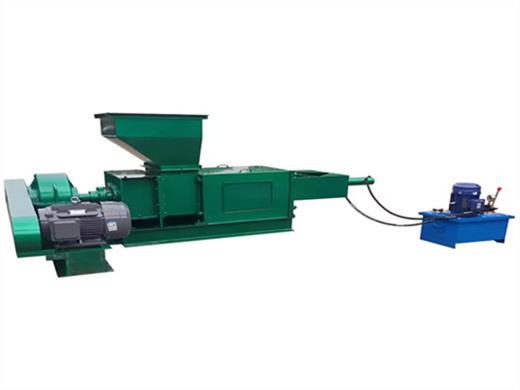

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Sunflower Oil Press Machine and Sunflower Oil Refinery

- Type: cooking oil refining machine

- Production capacity: 80kg/h~600kg/h

- Power (W): 5.5~18.5KW

- Voltage: Match local voltage

- Dimension (L*W*H): according to the capacity of the walnut oil pressing machine

- Weight: according to the capacity of the walnut oil press machine

We can provide the edible oil refinery production machine from 1 ton to 600 tons. The popular capacity is mini edible oil refinery machine from 1-5 tons, small scale oil refinery from 5-20 tons and other oil refinery from 20-600 tons. Our equipment suitable for various edible oil refining machine.

Sunflower seeds are of two types. One the non-oil seed which is usually eaten as confectionery just after being roasted with or without the shell. The other one is oil type seeds which is used for extracting oil. Below is a basic process of sunflower oil pressing. If you are looking for customized business plan for both small scale and large scale sunflower seed oil processing, don't hesitate to contact us and inquire for the most suitable equipment list and cost!

PHYSICAL REFINING OF SUNFLOWER OIL

- Raw Material: sunflower

- Press series: Second

- Raw material: Sesame, peanut, sunflower seed, soybean

- Voltage: 220 V

- Yield: High oil output rate

- Material: Stainless steel

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

How is oil used in Democratic Republic of the kenya? Oil supply. Oil-based fuels power millions of automobiles, aircraft and ships around the world and are integral. Currently, kenyalese oil production is limited to the Coastal Basin, yielding 25,000 barrels per day of offshore production, all of which is exported. Along with recently