Oilseed Processing | Oilseed Preparation | Bühler Group

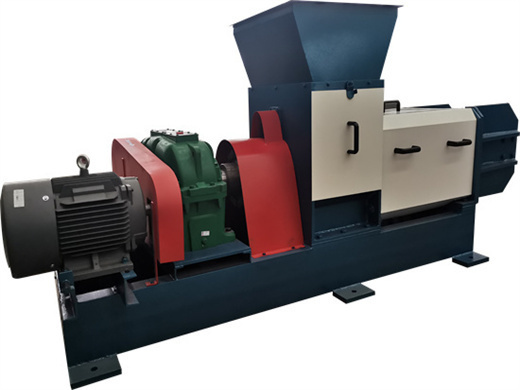

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 98---100%

- Voltage: 380V

- Main components: motor, pressure vessel, pump, motor, tank, filter, meter box

- Weight: 2000 KG

- Dimension (L*W*H): 4200*830*1800mm

- Country: afghanistan

Our sunflower preparation solution delivers excellent dehulling results leading to a higher protein content in your extraction meal. We can offer you tailored designs to meet your process and plant requirements, and implement one or two-stage sunflower dehulling, with single or double hull control, backed by global support.

laing Mill. - Bühler Group

- Type: sunflower oil processing machine

- Production capacity: 5TPD-100TPD, 3000-400kg/h

- Voltage: 380V/50HZ/Three-phase

- Main components: Motor

- Weight: 750 KG

- Dimension (L *W*H): 2280 *700*780mm

The flaking mill for all kinds of oilseeds. This modern and sturdy flaking mill is designed for the flaking of cracked soybeans and soft seeds such as sunflower kernels, rapeseed and corn (maize) germs. Other seeds and a wide range of different raw materials can also be processed. Mode of operation.

Flaking is at the heart of the sunflower preparation process and is of central importance to achieve high yields in the downstream pressing or solvent extraction. Our flaking mills are characterized by achieving maximum throughputs while providing a precise, smooth and vibration-free operation.

Flaking Mill DOQB | Oilseed Processing - Bühler Group

- Usage: sunflower oil

- Production capacity: 200 kg/h

- Voltage: 220 V

- Processing: 13 (kg/h)

- Power: 1.6 kW

- Dimension (length x width x height): 45 x 18 x 30 cm Weight: 42 .5kg Main Components: EngineOil Product Product Product Function: Peanut Oil Extraction

The flaking mill DOQB is used in oilseed preparation and handling to flake cracked soybeans and soft oilseeds such as sunflower seed, canola and corn germs. Proven technology and high reliability make this a machine you can rely on.

flaking mill and its ability to produce consistently thin flakes are key to the efficient extraction of all oilseeds. A promise guaranteed by Bühler. Weighing and cleaning Rapeseed Flakes Pre-Conditioning Flaking Preparation of soft seeds. Consistently thin flakes for efficient extraction. Related Bühler machines: – Scale – Cleaning Machines

Sunflower Impact Dehuller. DGBB. - Bühler Group

- Type: cooking oil extraction machine

- Production capacity: 100-500 tons

- Power (W ): Depends on the cooking oil manufacturing machines production every day

- Voltage: 380 V 440 V

- Dimension (L*W*H): Depends on the cooking oil manufacturing machines capacity

- Weight: According to the production of cooking oil making machines

The sunflower impact dehuller is an essential element in Büh-ler's sunflower preparation process. All components are se-amlessly matched to ensure maximum performance, efficien-cy, and product quality. The process chain consists of the following system components: Destoner and cleaners Dehulling technologies Flaking mills

The Bühler flaking mill DOQB is employed in the oilseed processing industry for the flaking of cracked soy beans and soft oil seeds such as sunflower, canola and corn germ. Proper oilseed flaking is a critical factor in the oil extraction process, as the seed's microscopic oil cells are ruptured, allowing the extraction media to penetrate the

Flaking Mill DOQB - Bühler Group - PDF Catalogs | Technical

- Raw Material: sunflower

- Production capacity: 100%2 to 5 ton hydraulic oil press

- Power (W): Depends

- Voltage: local voltage

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 30 tons

Optimum flaking through proven technology. The Buhler flaking mill DOQB meets today’s requirements in the oilseed processing as well as in applications in the feed processing industries. It is employed in the oilseed preparation and handling for the flaking of cracked soy beans and soft oilseeds such as sunflower, canola and corn germ.

When it comes to oilseed preparation, Bühler is the natural choice of partner for processing soybeans, rapeseed, sunflower and various other oilseeds. The company offers high-availability technology for the preparation of oilseeds prior to extraction.