Sunflower Oil : Everything we need to know - Oil Expeller

- Type: sunflower oil expeller

- Usage/Application: sunflower

- Production capacity: 1-500T/D

- Voltage:220V/380V

- Weight:30 tons

- Dimension (L*W*H )):46*32*12m

- Power ( W): 10-50kw

- Country: lagos

The sunflower oil is obtained through expeller pressing or solvent extraction methods, and than it is sent for oil filtration or oil refining and processed for various applications, including culinary use, skincare products, and industrial purposes such as biodiesel production. The resulting sunflower oil is a versatile and widely used product

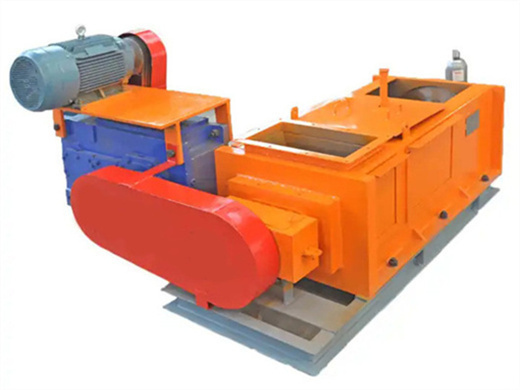

SMALL-SCALE SUNFLOWER OIL EXPELLING TECHNOLOGY

- Type: sunflower oil processing machine

- Production capacity: 200kg/h-2000kg/h

- Voltage: 220V/380V

- Main components: Motor, gear

- Weight: 780 KG

- Dimension (L*W*H): 1600x1100x1550mm

conditioners, oil expeller, filtration units / pumps, storage tanks Oil refining costs 1. Small-scale expelling Oil expellers with the capacity 50 to 300 kg seed per hour are regarded as small-scale. These are the typical on-farm and non-industrial units presently supplied to SMME’s. Typical examples are the Reinartz expeller AP VII (SLIDE).

high oleic sunflower oil Market Size was estimated at 1.5 (USD Billion) in 2023. The High Oleic Sunflower Oil Market Industry is expected to grow from 1.59(USD Billion) in 2024 to 2.5 (USD Billion) by 2032.

Expellers in edible oil production – Everything you need to

- Usage: sunflower oil

- Voltage: 380V-415V

- Power (W): depends on cooking oil machine mode

- Certification: CE, BV,ISO9001

- Weight: depends on the mode of cooking oil machine

- Dimension (length x width x height): depends on mode of cooking oil machine

As you can see, no matter the type of extraction process, mechanical techniques and oil expeller machines are mainstays of the edible oil industry. 3. Anatomy of an oil expeller press machine An oil expeller press is the heart and soul of any oil extraction operation. This essential piece of equipment uses pressure to separate oilseeds, nuts or

The following steps you need to set up an edible oil manufacturing business: Step 1. Learn more about the business. Learn more about the business is the first step to start an oil mill company. Study the requirements of cooking oil manufacturing business in terms of technology, capital, market and competition.

Walnut Oil Expeller Machine in lagos

- Type: cooking oil extraction machine

- Production capacity: 5-500 TPD

- Weight: 500 TONS

- Voltage: 440 V

- Certification: ISO,CE

- After-sales service provided: Engineers available to service machinery abroad.

What is hydraulic walnut oil expeller? Hydraulic walnut oil expeller is suitable for small and medium walnut oil processing plant and private oil mill. This walnut oil extraction machine is also suitable for processing coconut, peanut, soybean, camellia seed, flaxseed, rapeseed, sesame, cottonseed, sunflower seed, castor seed, tung seed, etc. 1. What is groundnut oil expelling machine

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

- Raw Material: sunflower

- Production capacity: 50-1000 kg/h

- Dimension (L*W*H): according to specification

- Voltage: 380 V

- Weight: 40 tons

- Warranty: 2 years

Production Process for Sunflower Seed Oil; Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent

Sunflower Oil Production Process: 1. Cleaning: The seeds are cleaned to remove foreign matter. 2. Dehulling: The seeds are dehulled to remove the outer shell. 3. Pressing/Expelling: The cleaned and dehulled seeds are fed into the oil expeller, where oil is extracted. 4. Filtration: The crude oil is filtered to remove solid impurities. 5.